Why Understanding Foam Insulation Types Matters for Your Home

Foam insulation types fall into two main categories that solve different problems in your home. If you’re dealing with high energy bills, drafts, or uncomfortable temperature swings, knowing which type works best for your space can save you thousands of dollars over time.

Quick Answer: The Main Foam Insulation Types

- Spray Foam – Liquid foam that expands to fill gaps, available as open-cell (R-3.6 per inch) or closed-cell (R-5.7+ per inch)

- Rigid Foam Board – Pre-formed panels like EPS, XPS, and Polyiso (R-3.6 to R-6.5 per inch)

- Injection Foam – Retrofits existing walls without removing drywall

- Pour Foam – Fills masonry blocks and existing wall cavities

- Can Foam – Small-scale sealant for gaps around windows and doors

Each type serves different applications. Spray foam excels at sealing irregular spaces and creating air barriers in attics, crawl spaces, and rim joists. Rigid boards work best on flat surfaces like basement walls, roof decking, and exterior wall sheathing.

The key difference? Spray foam expands and seals as it cures, blocking both heat transfer and air movement. Rigid boards provide consistent R-value but require careful sealing at joints to prevent air leaks.

Your choice depends on where you’re insulating, your budget, and whether you need maximum R-value per inch or just a solid thermal barrier. Professional installation matters too—spray foam requires specialized equipment and expertise, while rigid boards can sometimes be DIY-friendly.

I’m Dave Brocious, founder of ClimaShield Industries. With 20 years in the coatings industry and thousands of installations, I’ve seen how choosing the right foam insulation types transforms homes from drafty energy drains into comfortable, efficient spaces.

The Two Main Categories: Spray Foam vs. Rigid Foam Board

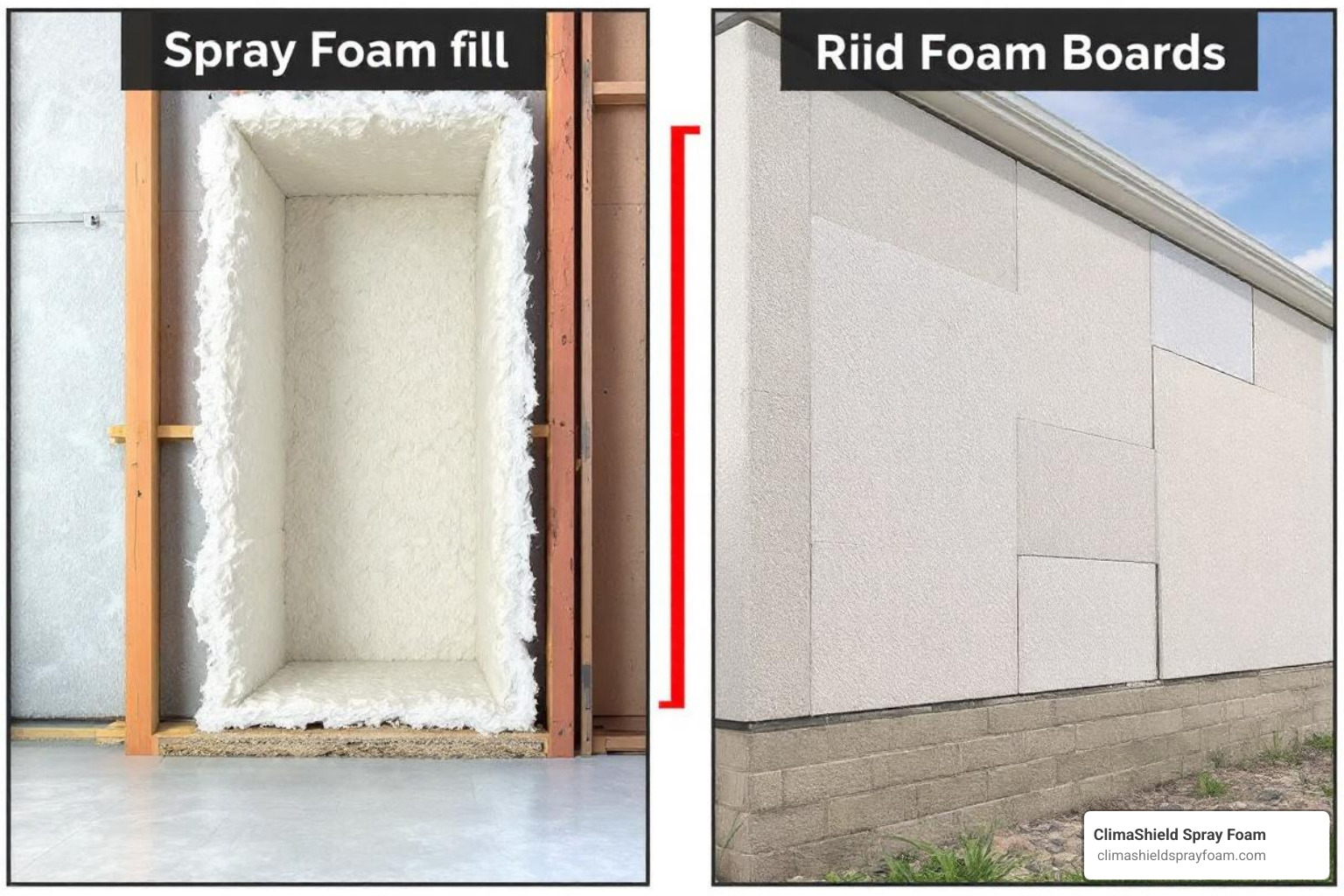

When discussing foam insulation types, we focus on two main categories: spray polyurethane foam (SPF) and rigid foam boards. Both boost your home’s energy efficiency but in different ways. Spray foam is like a custom-fit suit, contouring to every curve, while rigid foam board is a sturdy, precisely cut panel for flat surfaces.

Spray Polyurethane Foam (SPF) is applied as a liquid that expands and cures into a solid foam. This allows it to fill every nook and cranny, creating a seamless barrier. It’s versatile, adds structural support when properly installed, and its unparalleled air-sealing capabilities are a huge win for energy savings by preventing air infiltration.

On the other hand, rigid foam panels are pre-formed sheets of insulation (EPS, XPS, or Polyiso) that are cut to fit. They offer consistent R-values and are great for continuous insulation on flat surfaces like walls or roofs. However, all joints and seams must be carefully sealed to prevent air leaks. These robust boards provide a strong, durable thermal barrier.

The installation process is a key differentiator. Spray foam is a complex chemical process requiring professional expertise and specialized equipment. Rigid foam boards, while needing precision, can sometimes be more DIY-friendly for certain projects, though professional guidance is always recommended for optimal performance. Understanding their strengths is the first step in choosing the right solution. For more details on insulating your home, check out our insights on residential insulation.

Spray Foam: The Expansive Sealant

Spray foam insulation seeks out and expands to fill every gap, creating a powerful barrier against energy loss. Applied as a liquid that rapidly hardens, this unique product conforms perfectly to any surface, from uneven attic joists to wall cavities. Spray foam is categorized into open-cell and closed-cell, which we’ll detail shortly. Both create a robust air barrier that significantly reduces drafts and air leakage, a major source of energy loss in homes.

Due to specialized equipment and precise chemical ratios, spray foam requires professional installation. Our certified installers handle the two-component system (isocyanate and a polyol blend) safely, ensuring optimal performance. The result is a seamless barrier that insulates, seals, and can act as a moisture/vapor barrier depending on the type. Explore the many uses of spray foam to learn more.

Rigid Foam Board: The Sturdy Panel

Rigid foam boards are an excellent choice for a consistent thermal barrier on flat surfaces. These pre-formed sheets come in various materials, each with unique characteristics, high R-values, and durability for specific applications. These boards are cut and fastened to surfaces like exterior walls or roof decks. Since they don’t expand, sealing all seams and joints with tape or sealant is critical to prevent air leaks. Properly installed, they form a continuous insulation layer, minimizing thermal bridging (heat loss through framing).

Among the rigid foam board options, you’ll commonly find:

- Expanded Polystyrene (EPS): The most budget-friendly option (R-value 3.6-4.2 per inch), this versatile white foam is used for roofs, walls, and under slabs.

- Extruded Polystyrene (XPS): Known by its blue, green, or pink color, XPS has a higher R-value (~5 per inch) and excellent moisture resistance, ideal for basements and foundations.

- Polyisocyanurate (Polyiso): With the highest R-value (avg. 6.5 per inch), this foil-faced foam is a popular choice for roofs and exterior walls.

Rigid foam boards are favored for their consistent R-value and ease of handling on flat surfaces. Their strength is important for applications like roofs or under slabs. While sealing is critical, their straightforward application makes them a reliable choice.

A Closer Look at Spray Foam Insulation

Professional spray foam is a sophisticated two-component system, far different from canned foam. It starts as two separate liquids, an isocyanate and a polyol blend, kept in separate drums. These are heated and pumped through hoses to a spray gun.

At the spray gun tip, the liquids mix, causing a rapid chemical reaction. The mixture expands dramatically into a dense foam, filling every cavity to create a seamless insulation layer. This creates an unparalleled air barrier, key to boosting energy efficiency. The cured foam adheres strongly, forming a durable barrier that regulates temperatures, reduces drafts, and can even be pest resistant.

Comparing Open-Cell and Closed-Cell Foam Insulation Types

When we talk about spray foam, the conversation almost immediately turns to the two primary types: open-cell and closed-cell. The names essentially describe their internal structure, and these differences lead to distinct properties and applications. Knowing the difference is crucial for choosing the right foam insulation type for your specific needs.

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| Density | Low-density (approx. 0.5 lbs/ft³) | Medium-to-High density (approx. 2.0-3.0 lbs/ft³) |

| R-Value per inch | Around 3.6 per inch | Starting at 5.7 per inch, up to 6.5 per inch |

| Structure | Flexible, sponge-like, cells are not fully enclosed | Rigid, dense, cells are fully encapsulated |

| Air Barrier | Excellent | Excellent |

| Vapor Barrier | Vapor permeable (allows moisture to pass through) | Vapor retarder/barrier (blocks moisture) |

| Moisture Resistance | Absorbs water (not for flood-prone areas) | Resists water absorption (good for below-grade) |

| Expansion | Expands significantly, fills large cavities easily | Expands moderately, provides structural rigidity |

| Sound Dampening | Good (NRC score of 0.75) | Moderate (STC score of 37-39) |

| Cost | Generally more cost-effective | Higher cost due to density and material composition |

| Applications | Interior wall cavities, attics, soundproofing | Exterior walls, attics, crawl spaces, basements, roofs |

Open-Cell Spray Foam is like a soft, flexible sponge. Its cells are not completely enclosed, allowing air to fill the spaces within the foam. This makes it incredibly expansive, filling large cavities with ease and providing an excellent air seal. With an R-value of around 3.6 per inch, it’s a cost-effective choice for interior walls and attics. Its soft texture also provides fantastic sound dampening (NRC 0.75). However, open-cell foam is vapor-permeable and absorbs water, making it unsuitable for moisture-prone areas like basements without additional moisture management.

Closed-Cell Spray Foam, on the other hand, is much denser and more rigid. Its cells are completely encapsulated, trapping a gas that contributes to its superior insulating properties and high R-value (starting at 5.7 per inch). Closed-cell foam creates an effective air, vapor, and water barrier, ideal for exterior applications, basements, and crawl spaces. Its rigidity adds structural strength, and it’s highly moisture-resistant. While costlier, its robust performance makes it a top-tier choice for durability and maximum energy efficiency. Closed-cell spray foam is not a food source for mold, a key benefit in moisture-managed environments. Learn more in our article, Is Spray Foam Insulation Mold Resistant?.

Primary Applications and Costs

Understanding where each foam insulation type shines is key to making an informed decision.

Spray Foam Applications:

- Attics: Both open-cell and closed-cell are fantastic for attics. Closed-cell is particularly effective in unvented attics, creating a sealed, conditioned space that prevents heat transfer through the roof deck. Open-cell can be used in vented attics or for sound dampening in interior attic spaces.

- Crawl Spaces and Basements: Closed-cell spray foam is our go-to here. Its superior moisture resistance and ability to create an air and vapor barrier make it perfect for these damp-prone areas, protecting your home from humidity and foundational issues.

- Rim Joists: This is a common area for air leaks and energy loss. Spray foam, especially closed-cell, perfectly seals these often-overlooked spaces, creating a tight barrier.

- New Construction Walls: Whether it’s open-cell for interior walls (where sound dampening and cost-effectiveness are priorities) or closed-cell for exterior walls (for maximum R-value and structural integrity), spray foam provides a continuous, high-performance insulation layer.

Costs:

Spray foam cost is measured in “board feet” (one square foot, one inch thick). Prices vary by foam type, thickness, and project complexity. While the upfront cost is higher than traditional materials, the investment provides a significant return. Our Pennsylvania customers often see energy bill savings up to 60%! The superior air sealing and high R-value lead to a more comfortable home and lower long-term costs, an investment that pays for itself over time by lowering your energy bill.

Understanding Rigid Foam Insulation Types

Rigid foam insulation boards are the unsung heroes for many building projects, especially where flat, consistent surfaces need a strong thermal barrier. These boards offer a high R-value per inch, making them incredibly efficient at stopping heat flow.

The R-value of rigid foam boards varies significantly by type. For instance, Expanded Polystyrene (EPS) might offer an R-value range of 3.6 to 4.2 per inch, while Extruded Polystyrene (XPS) typically provides roughly 5 per inch. Polyisocyanurate (Polyiso) often leads the pack with an average R-value of 6.5 per inch. This means you can achieve impressive insulation performance with less thickness compared to some other materials.

Beyond R-value, other properties are crucial. Compressive strength is important for applications where the insulation will bear weight, like under concrete slabs or on roofs. Many rigid foam boards also come with facings, such as foil or plastic, which can serve multiple purposes: protecting the foam, acting as a radiant barrier, or enhancing its performance as an air or vapor barrier.

Moisture resistance is another key factor. XPS, with its closed-cell structure, is known for its excellent moisture resistance, making it suitable for below-grade applications where dampness is a concern. Polyiso, while having a high R-value, can be more susceptible to moisture absorption than XPS if its facings are compromised. The cost of rigid foam boards varies, with XPS, for example, costing around 42¢ per square foot for a 1-inch-thick 4×8 panel.

Understanding these properties helps us select the right rigid foam board for your specific project, ensuring optimal performance and longevity. You can learn even more about various insulation materials and their applications on our page dedicated to residential insulation.

Rigid Foam Board Options Offered by ClimaShield

At ClimaShield, we understand that every project in Indiana, PA, and across Pennsylvania has unique requirements. That’s why we work with a range of rigid foam board options, carefully selecting the right material for the job based on its properties and suitability.

While we specialize in spray foam, we recognize the value of rigid foam boards for specific applications:

- Expanded Polystyrene (EPS): This is a versatile and budget-friendly option, offering an R-value range of around 3.6 to 4.2 per inch. It’s often used for sheathing, in structural insulated panels (SIPs), and under concrete slabs. EPS is known for its stable R-value over time and good moisture resistance, especially when used in ground contact. Its light weight and ease of cutting make it adaptable for many projects.

- Extruded Polystyrene (XPS): With an R-value of roughly 5 per inch, XPS provides superior moisture resistance compared to EPS due to its dense, closed-cell structure. This makes it an excellent choice for below-grade applications like basement walls and foundations, where moisture can be a significant issue. However, it’s important to note that XPS can sometimes experience a slight reduction in R-value over very long periods due to gas diffusion.

- Polyisocyanurate (Polyiso): This material boasts the highest R-value among rigid foam boards, averaging 6.5 per inch. Often faced with foil, Polyiso is a prime choice for roofs and exterior walls. It also contains some recycled materials, making it a more eco-conscious option. However, its R-value can be affected by very cold temperatures, and it’s generally not recommended for direct below-grade contact unless specifically designed and protected.

When considering rigid foam boards, it’s crucial to remember that interior applications must be covered with a 1/2-inch gypsum board or other building-code approved material for fire safety. Similarly, exterior applications require a weatherproof facing. We ensure that the foam insulation types we recommend and install meet all local building codes and perform optimally for the specific conditions of your project.

Key Considerations for Your Project

Choosing the right foam insulation type for your home is a big decision, and it’s one we help our customers in Pennsylvania steer every day. It’s not just about picking the highest R-value; it’s about matching the insulation to your project’s unique needs, your budget, and even your health and safety priorities.

First, think about the project location. Are we talking about a drafty attic, a damp basement, new construction walls, or a crawl space? Each area presents different challenges and requires specific insulation properties. For instance, a basement often needs insulation that can handle moisture, while an attic might prioritize maximum thermal resistance. We even offer specialized services like air sealing basements to ensure comprehensive protection.

Next, consider the installation process. Some foam insulation types are more labor-intensive and require professional expertise, while others might be more DIY-friendly. We always emphasize that proper installation is paramount for performance. Even the best insulation won’t deliver if it’s not installed correctly.

Health and safety are also top-of-mind. While foam insulation is safe once cured, the installation process, particularly for spray foam, involves chemical reactions that require strict safety protocols. We’ll discuss this in more detail shortly.

Finally, eco-friendliness and your budget play significant roles. Some foam types incorporate recycled content, and while spray foam typically has less, its long-term energy savings often make it a very sustainable choice. Balancing the upfront cost with the long-term benefits and environmental impact is a conversation we’re happy to have with you.

If you’re comparing insulation types more broadly, resources like the U.S. Department of Energy’s overview of types of insulation can help you understand how foam stacks up against other options.

Installation Differences Between Foam Insulation Types

The way different foam insulation types are installed varies dramatically, and these differences are crucial to understanding their suitability for your project.

- Spray Foam: This is a job for the pros, no question about it. We use specialized equipment—high-pressure pumps, heaters, and spray guns—to apply the two liquid components that mix and expand on contact. This process requires precise temperature control, mixing ratios, and application techniques to ensure proper curing, adhesion, and performance. Our certified technicians wear extensive personal protective equipment (PPE) and ensure proper ventilation during installation.

- Injection Foam: Designed specifically for retrofitting existing walls without removing drywall, injection foam involves drilling small holes into the wall cavities. The foam, which often has a consistency similar to shaving cream, is then pumped into these spaces, expanding gently to fill the void. This method is also highly specialized and requires professional expertise to avoid over-pressurizing walls or creating gaps.

- Pour Foam: Similar to injection foam but often used for masonry blocks or existing wall cavities, pour foam is carefully poured or injected into the desired space. Closed-cell pour foam, for example, is excellent for insulating concrete bricks and blocks in commercial masonry applications, while open-cell pour foam can be used for existing residential wall cavities.

- Foam Board: Installation of rigid foam boards is more straightforward but still requires precision. Boards are cut to fit, then fastened to surfaces. The critical step here is carefully sealing all seams and joints with tape or caulk to prevent air leaks. While some homeowners might attempt this for smaller projects, ensuring a continuous, airtight barrier across a large area often benefits from professional experience.

- Can Foam: This is the most DIY-friendly of the foam types. Can foam, like Great Stuff by Dupont, comes in pressurized canisters and is used to fill small gaps, cracks, and seal around windows and doors. It expands in place and is excellent for air-sealing small penetrations, but it’s not designed for insulating large areas.

Health, Safety, and Sustainability

Health and safety are paramount, especially with the chemical reactions in spray foam. The primary concern during installation is exposure to Methylene Diphenyl Diisocyanate (MDI), which can harm workers’ lungs. That’s why our professional installers use extensive personal protective equipment (PPE), including respirators, and ensure proper ventilation. The U.S. EPA shares these concerns; you can find more information in the EPA’s guidance on spray foam safety.

After installation, spray foam needs a specific curing time, during which the chemicals fully react and off-gassing occurs. We adhere to strict re-occupancy guidelines, ensuring your home is safe to re-enter only after the foam has fully cured and any airborne contaminants have dissipated. Once cured, spray foam is inert and considered safe.

From a sustainability perspective, foam insulation types have varying profiles. Spray foam insulation currently contains very little recycled content. However, its exceptional energy-saving capabilities significantly reduce a home’s carbon footprint over its lifetime. Rigid foam boards like Polyiso contain roughly 9% recycled materials, offering a slightly higher recycled content. While we focus on foam, it’s interesting to note that other insulation materials like cellulose (often 80% or more recycled content) and mineral wool (10-90% recycled content) lead in this aspect.

Blowing agents are also a consideration. Older foam products used ozone-depleting substances, but modern formulations use more environmentally friendly alternatives. We stay updated on the latest advancements to ensure we’re using the safest and most effective products available.

Finally, foam insulation, especially closed-cell, is not a food source for mold. This is a significant advantage, as mold needs moisture and a food source to grow. By creating an airtight, moisture-resistant barrier, we help manage your home’s environment for a healthier living space.

Frequently Asked Questions about Foam Insulation

Which foam insulation has the highest R-value?

Rigid foam boards and closed-cell spray foam offered by ClimaShield both provide high R-values per inch. Closed-cell spray foam typically starts at R-5.7 per inch and can go up to R-6.5 per inch, while Polyisocyanurate (Polyiso) rigid foam board also averages 6.5 per inch. The final R-value of a system depends not just on the material itself, but on proper installation and creating an effective air seal, where spray foam often excels by filling every void.

Can I install spray foam insulation myself?

While DIY kits exist, professional installation is strongly recommended for spray foam. The process involves a chemical reaction that requires precise temperature, pressure, and mixing ratios to ensure safety, performance, and proper curing. Improper installation can lead to poor R-value, incomplete expansion, and potential health risks from uncured chemicals. Our certified professionals have the training, experience, and specialized equipment to ensure a safe, high-quality, and effective installation for your Pennsylvania home.

Is foam insulation a good investment?

Yes, foam insulation is an excellent investment. Its high R-value and superior air-sealing capabilities can significantly reduce heat loss in winter and heat gain in summer, leading to substantial savings on energy bills. Many of our customers in Indiana, PA, and surrounding areas experience up to 60% reduction in their energy costs. It also improves home comfort by eliminating drafts and temperature fluctuations, improves indoor air quality, and can increase property value. Over its lifetime, the energy savings often far outweigh the initial investment.

Conclusion

Choosing the right foam insulation type is a critical decision for any homeowner looking to improve comfort and reduce energy bills. As we’ve explored, whether it’s the expansive, air-sealing power of spray foam or the sturdy, high-R-value panels of rigid foam board, each type offers distinct advantages custom to different applications.

For complex, irregular spaces like attics, crawl spaces, and rim joists, spray foam offers a superior, seamless air barrier that can transform your home’s energy performance. For flat surfaces, exterior sheathing, or below-grade applications, rigid foam boards provide a durable and effective thermal solution.

The “best” choice depends on your specific project, budget, and performance goals. That’s where our expertise comes in. A professional assessment from ClimaShield Spray Foam ensures you get not only the most effective foam insulation type for your unique needs but also the highest quality installation, guaranteeing decades of comfort and energy savings.

For expert guidance on the right insulation solution for your home or business in Indiana, PA, or anywhere in Pennsylvania, consult with the professionals at ClimaShield Spray Foam. We’re here to help you make an informed decision that will keep your home comfortable and your energy bills low. Explore the many uses of spray foam and let us help you achieve superior energy efficiency.