Introduction: Stop Paying to Heat the Outdoors

Air sealing basement spaces is the process of closing gaps, cracks, and penetrations where air leaks in and out of your home’s foundation. Here’s what you need to seal:

Key Areas to Air Seal in Your Basement:

- Rim joists – where floor framing meets the foundation wall

- Sill plates – the gap between foundation and wood framing

- Foundation cracks – in poured concrete or block walls

- Utility penetrations – around pipes, wires, ducts, and vents

- Basement windows and doors – frames and rough openings

- Sump pits – unsealed covers allow constant air infiltration

- Subfloor gaps – seams and penetrations in the floor above

Your basement could be costing you hundreds annually in wasted energy. If you have high heating bills, cold floors, or uncomfortable rooms, air leaks in your basement are a likely culprit.

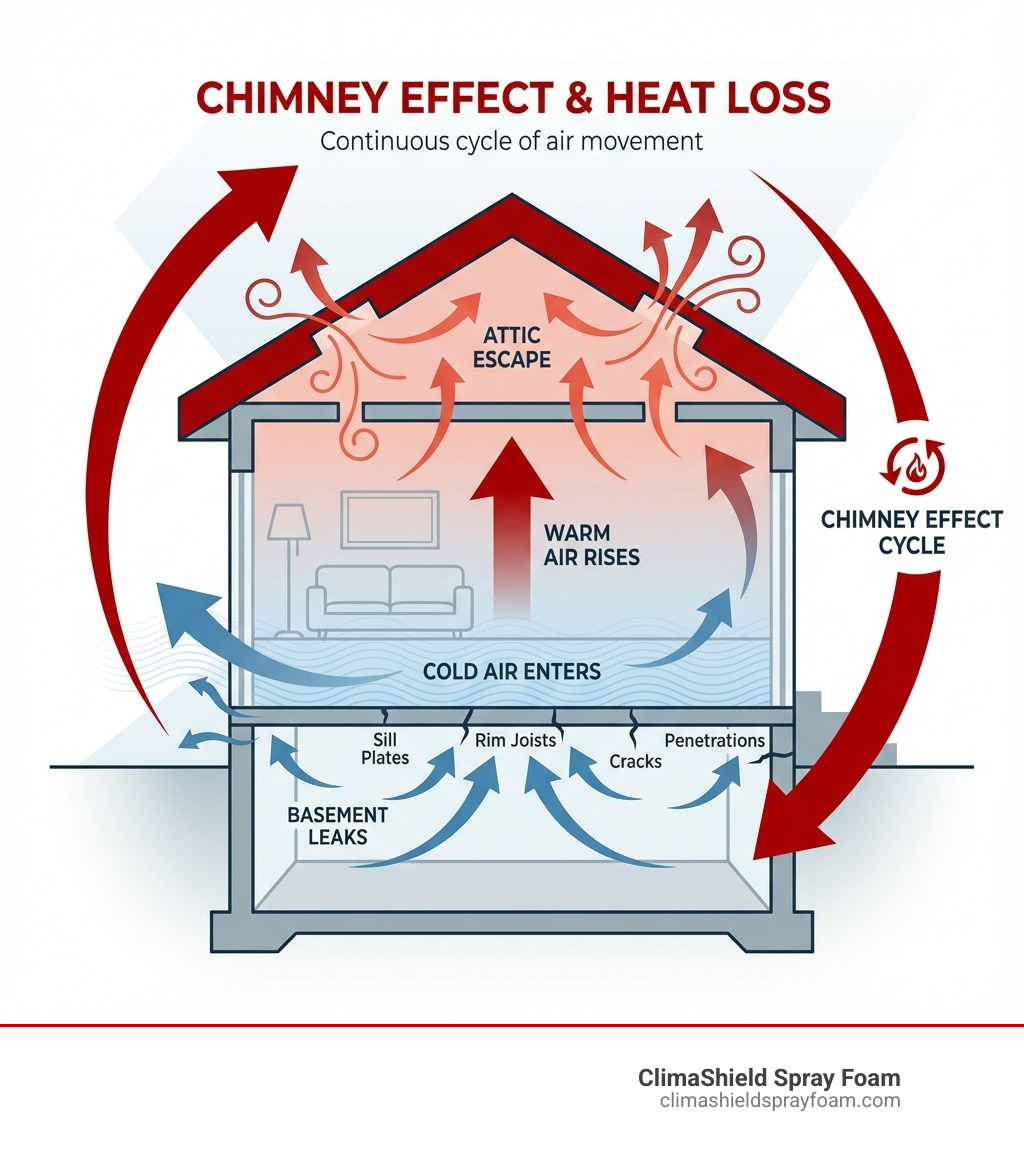

The problem isn’t just your basement being cold. It’s something called the chimney effect or stack effect. When warm air escapes through your attic, it creates a vacuum that pulls cold air into your home through basement leaks. Your furnace works overtime to replace that escaping heat, driving up your energy bills by 20-40% according to research.

Think of your house like an open chimney. Hot air rises and exits through the top (your attic), while cold outside air rushes in through the bottom (your basement) to replace it. Sealing basement air leaks stops this cycle at the source.

The most common places air enters basements are around windows and doors, between the concrete foundation and the mudsill (sill plate), and at rim joists where your floor framing sits on the foundation. You’ll also find leaks around every pipe, wire, and duct that penetrates your basement ceiling or walls.

Proper air sealing can cut your energy use by 20-40%. That’s real money back in your pocket, plus a warmer, more comfortable home.

I’m Dave Brocious, founder of ClimaShield Industries. With 20 years of experience in specialty coatings and insulation, I’ve helped countless homeowners solve their energy problems with professional air sealing basement applications using spray foam insulation, and I’ll show you how it’s done.

Identifying Basement Air Leaks: Your Home’s Energy Blueprint

Before tackling those pesky leaks, we must find them. Think of it as detective work to find where your home is losing energy. Identifying basement air leaks is the first step toward a more comfortable, energy-efficient space.

DIY Leak Detection: Your First Line of Defense

You don’t always need fancy equipment to spot the most obvious culprits. Here are a few DIY methods we recommend:

- The Hand or Feather Test: On a cold or windy day, simply hold your hand or a feather near common leak areas like windows, doors, and where the foundation meets the wood framing. If you feel a draft or see the feather flutter, you’ve found a leak!

- Visual Inspection: Look for visual cues. Are there dirty spots on existing insulation? This often indicates air movement filtering dusty air through a gap. In colder weather, frosty areas on insulation can signal warm, moist air condensing as it escapes. In warmer weather, you might even spot water staining in these areas.

- The Exhaust Fan Trick: For a more comprehensive DIY test, turn on all your home’s exhaust fans (bathroom fans, kitchen range hood, dryer, central vacuum) to create negative pressure. This mimics a professional blower-door test on a smaller scale and can make drafts more noticeable when performing the hand or feather test.

Professional Leak Detection: For a Deeper Dive

While DIY methods find obvious leaks, a professional energy audit can pinpoint hidden air infiltration pathways. We use specialized tools for a thorough assessment:

- Blower-Door Test: This is the gold standard for identifying air leaks. A large fan is mounted in an exterior doorway, depressurizing the house. This exaggerates air leaks, making them easier to detect with smoke pencils, infrared cameras, or even just your hand. A blower-door test helps us quantify your home’s overall airtightness and locate those elusive leaks.

- Infrared Imaging: Infrared cameras can reveal temperature differences that indicate air leakage and insulation gaps. Cold spots in winter or warm spots in summer often correspond to areas where conditioned air is escaping or unconditioned air is entering.

- Smoke Pencils/Puffers: These tools emit a harmless stream of smoke or vapor that visibly reacts to air currents, making even small leaks easy to see.

Once these leaks are identified, sealing them with spray foam offers numerous benefits. It not only improves comfort by eliminating drafts and stabilizing indoor temperatures but also significantly contributes to lowering Your Energy Bill.

The Top 7 Hotspots for Basement Air Leaks

Based on our experience in Pennsylvania homes, and supported by industry research, these are the primary areas where we consistently find air leaks in basements:

- Rim Joists & Sill Plates: This is often the biggest culprit. The rim joist is the wooden band that forms the perimeter of your floor framing, sitting directly on top of your foundation wall. The sill plate (or mudsill) is the wood member between the foundation and the rim joist. Gaps here, both at the bottom and top of the rim joist, allow cold air to stream in.

- Foundation Cracks: Poured concrete or concrete block foundations can develop cracks over time due to settling or hydrostatic pressure. Even hairline cracks can be significant pathways for air (and moisture).

- Basement Windows & Doors: Old, poorly sealed windows and bulkhead doors are notorious for drafts. Look for gaps around the frames where they meet the foundation, and assess the condition of weatherstripping.

- Utility Penetrations: Every pipe, wire, duct, or vent that passes through your basement walls or ceiling creates a potential opening. These include electrical conduits, water supply lines, drain pipes, gas lines, and dryer vents. Plumbers and electricians often cut larger holes than necessary, leaving significant gaps.

- Sump Pits: An open or poorly sealed sump pit acts like a direct pipeline for cold, damp air (and potentially radon gas) from the ground into your basement.

- Gaps in the Subfloor: If your basement ceiling is unfinished, look up! Gaps between subfloor boards, especially in older homes with diagonal lumber, or around penetrations for plumbing stacks, HVAC duct boots, or electrical wiring, can allow air to bypass your basement and enter the living spaces above.

- Chases and Chimneys: Any chases (enclosed shafts) or masonry chimneys that pass through your basement ceiling to the floors above can be significant sources of air leakage.

The Ultimate How-To Guide for Air Sealing Basement Leaks

Now that we know where to look, let’s discuss how to seal those leaks effectively. Our primary tool for a durable air sealing basement project is spray foam.

Choosing Your Tools: Why Spray Foam is the Superior Solution

While caulk has its place for very small cracks, and rigid foam boards are excellent for insulating, spray foam stands out as the superior solution for air sealing basements, especially in the varied and often challenging conditions of Pennsylvania homes.

| Feature | Spray Foam | Caulk | Fiberglass Batts (Insulation, not air seal) |

|---|---|---|---|

| Air Sealing Ability | Excellent – expands to fill irregular gaps, forms a continuous, airtight barrier. | Good for small, consistent gaps (<1/4 inch). | Poor – does not stop airflow; air easily passes through. |

| Insulation Value | Excellent (R-5.6 to R-6 per inch for closed-cell) – provides both air seal and insulation. | Minimal insulation value. | Good (R-3 to R-4 per inch) – but only if air sealed by another material. |

| Moisture Resistance | Excellent (closed-cell spray foam) – creates a vapor barrier, resists mold and water intrusion. | Varies by type; some are water-resistant, but not a true moisture barrier. | Poor – absorbs moisture, can lead to mold and reduced R-value. |

| Versatility | Fills gaps from 1/4 inch to 3+ inches, adheres to various materials, ideal for irregular surfaces. | Best for small, linear gaps; limited for larger or irregular openings. | Primarily for cavity filling; requires an air barrier. |

| Durability | Long-lasting, maintains integrity over time, resists pests. | Can dry out, crack, and shrink over time; less durable in high-movement areas. | Can sag, compress, and become ineffective if not properly installed/supported. |

| Ease of Application | Requires specialized equipment and training for large areas; DIY cans for smaller jobs. | Easy for small jobs; requires skill for neat, continuous beads. | Relatively easy to cut and fit; prone to gaps if not carefully installed. |

| Special Use Cases | High-temperature versions for flue pipes (with proper clearances); excellent for bump-outs. | High-temperature caulk for flues (first 3 inches); general purpose for small gaps. | Not suitable for air sealing or near hot surfaces. |

Spray foam’s ability to expand and conform to irregular surfaces, plus its superior insulation and moisture resistance, makes it the ideal material for effective air sealing basement projects. For gaps 1/4 inch or less, we might use caulk, but for anything larger, up to about 3 inches, expanding spray foam is our preferred method. For hot areas like furnace flues, we use specialized high-temperature caulk for the immediate area, adhering to strict clearance guidelines.

Step-by-Step: Sealing Rim Joists and Foundation Walls

These areas are often responsible for the most significant air leakage in your basement. Addressing them is crucial.

- Preparation is Key: Before applying any sealant, clean the surfaces thoroughly. Remove any loose debris, dirt, or old crumbling caulk. A wire brush and a vacuum cleaner work wonders. Ensure the surfaces are dry for proper adhesion.

- Sealing the Sill Plate: This is the critical juncture where your wooden house frame rests on the concrete foundation. Even if it looks tight, tiny gaps here can allow a lot of air transfer. We carefully apply spray foam along this entire gap, ensuring a continuous seal between the foundation and the mudsill.

- Sealing Rim Joist Cavities: These are the open bays between your floor joists, directly above the foundation wall.

- Air Sealing First: We start by air sealing all cracks and gaps within the rim joist cavity itself. This includes the junctions between the foundation wall and the rim joist, and where the rim joist meets the subfloor above. Spray foam is ideal here because it expands to fill every void, creating an airtight barrier.

- Insulating the Rim Joist: After air sealing, we then add insulation. For maximum effectiveness, we often use additional closed-cell spray foam or rigid foam insulation cut to fit snugly within each cavity. This creates a complete thermal barrier. Fiberglass batts, while good for insulation, do nothing to stop airflow on their own, so they should only be added after a thorough air seal is established.

- Bump-Out Areas: Pay special attention to “bump-out” areas like bay windows or cantilevered floors. These areas have more exposed rim joist surface and often present greater opportunities for air leakage. We ensure these are carefully sealed and insulated.

- Sealing Foundation Cracks:

- Poured Concrete or Block Walls: For hairline cracks, we often use a specialized silicone caulk that remains flexible. For larger cracks, we’ll use spray foam.

- Stone and Mortar Walls: Older homes in Pennsylvania might have stone or rubble foundations. For these, we first remove any loose material and then repair cracks with a durable mortar and small stones before applying any additional air sealing. Applying spray foam directly to a crumbling surface won’t last.

For more detailed information on various insulation methods and benefits, you can always check out More on Residential Insulation.

Tackling Penetrations, Floors, and Sump Pits

Beyond the main structural elements, many smaller but equally important areas need attention during an air sealing basement project.

- Sealing Around Pipes & Wires (Utility Penetrations): Every single hole drilled for electrical wires, water supply pipes, drain pipes, plumbing vent stacks, and gas lines is a potential leak. Plumbers and electricians often leave larger holes than necessary.

- Small Gaps: For gaps 1/4 inch or less, we use caulk.

- Larger Gaps: For anything larger, up to 3 inches, we use expanding spray foam. It’s crucial to seal all around these penetrations where they pass through your basement walls and ceiling to the floor above.

- Hot Flue Pipes: Special consideration is given to hot flue pipes from combustion appliances. For these, we use rolled sheet metal and high-temperature rated caulk for the first 3 inches outwards from the pipe, ensuring proper clearances and safety. Standard spray foam should not be used in these high-temperature areas.

- Sealing Subfloor Gaps: If your basement ceiling is unfinished, you might see the underside of the subfloor for the first floor.

- Between Boards: In older homes, subfloor boards might have gaps. We seal these seams with caulk or construction adhesive.

- Around Penetrations: Just like wall penetrations, plumbing stacks, HVAC duct boots, and electrical wiring passing through the subfloor need to be sealed. For large openings too big for canned spray foam, we custom-cut a piece of OSB, plywood, or rigid foam board to fit, then seal its edges with caulk or spray foam and mechanically fasten it.

- Sealing Sump Pit Covers for Airtightness: An open sump pit is a direct portal for cold, damp air and potentially radon gas. We recommend replacing any sump pit without a tight-fitting, airtight lid with a new, sealed unit. If replacing isn’t an option, we can often seal the existing lid to the floor with caulk or weatherstripping to reduce air leakage. Companies like Jackel offer excellent airtight sump pit solutions.

Critical Safety Precautions for Your Air Sealing Project

While air sealing basement areas offers tremendous benefits, proceed with caution and be aware of potential safety concerns. Our priority at ClimaShield Spray Foam is always the health and safety of your home and family.

Combustion Safety: Avoiding Backdrafting and CO Poisoning

One of the most critical considerations when tightening up your basement is the impact on combustion appliances.

- The Risk with Atmospherically Vented Appliances: Many older furnaces, water heaters, and boilers are “atmospherically vented.” This means they draw combustion air from the room they are in (the basement) and rely on natural draft to vent exhaust gases up a chimney. If you make your basement too airtight, these appliances can be starved for air.

- Backdrafting: An air-starved appliance might “backdraft,” meaning the dangerous exhaust gases (including carbon monoxide, or CO) are pulled into your home instead of venting safely outside. This is a serious health hazard.

- Carbon Monoxide: Carbon monoxide is a colorless, odorless, and tasteless gas that can be deadly. It’s crucial to have working carbon monoxide detectors on every level of your home, especially in the basement.

- The Importance of a Combustion-Safety Test: Before and after a significant air sealing basement project, especially if you have atmospherically vented appliances, we strongly recommend a combustion-safety test. A qualified professional will ensure your appliances have adequate combustion air and that your chimney draws properly.

- Sealed Combustion Units: For new installations or replacements, we highly recommend “sealed combustion” appliances. These units draw fresh outdoor air directly for combustion and vent exhaust gases directly outside, completely separate from your indoor air. This eliminates the risk of backdrafting and is the safest option for an airtight home.

Managing Radon, Mold, and Other Hazards during your air sealing basement project

Beyond combustion safety, there are other health and safety considerations to keep in mind for your air sealing basement project.

- Radon Gas Risks: Radon is a naturally occurring, odorless, colorless, and tasteless radioactive gas that seeps up from the ground and can enter your home through cracks in the foundation, gaps around pipes, and sump pits.

- How Air Sealing Relates: Sealing cracks in your basement can impact radon levels. In some cases, it can help reduce infiltration; in others, by making the basement more airtight and potentially creating negative pressure, it might concentrate existing radon.

- Pre-Sealing Radon Testing: The best way to know if your home needs radon-remediation work is to test the air in your home. If levels are high, a radon-remediation contractor can install mitigation systems (like sub-slab depressurization) to safely vent the gas outside. For more on radon testing and mitigation, visit the EPA guide to radon.

- Mold and Moisture Issues: Basements are naturally prone to moisture. If your basement has existing moisture problems (leaks, dampness, efflorescence, mold growth), these must be addressed before air sealing and insulating. Sealing a damp basement can trap moisture, leading to severe mold growth, rot, and poor indoor air quality. We always assess for water leaks, dampness, and cracks before we begin. For very wet basements prone to flooding, insulating the walls might not be advisable until the water intrusion is fully resolved.

- Electrical Safety (Knob & Tube Wiring): Older homes, especially those built before the 1930s in Pennsylvania, may have knob-and-tube electrical wiring. This type of wiring can be a fire hazard if it comes into direct contact with insulation, as it relies on air for cooling. If you have knob-and-tube wiring in your basement, consult with a qualified electrician before proceeding with any insulation or air sealing that might cover or encapsulate it.

Frequently Asked Questions about Basement Air Sealing

We hear a lot of great questions from homeowners in Indiana, PA, and across Pennsylvania about air sealing basement projects. Here are some of the most common ones.

What’s the difference between air sealing and insulating a basement?

It’s a common misconception that insulation alone stops air leaks. Think of it this way:

- Insulation is like a sweater: It slows down the transfer of heat. A thick sweater keeps you warm, but if it’s full of holes, the wind will still cut right through you. In your basement, insulation resists heat flow through walls and rim joists.

- Air sealing is like a windbreaker: It stops the movement of air. A windbreaker might not be as thick as a sweater, but it prevents cold drafts from reaching you. In your basement, air sealing closes the gaps and cracks that allow air to bypass your insulation.

Both are critical for an energy-efficient home, but they perform different functions. We always recommend air sealing basement areas before insulating to ensure maximum effectiveness and prevent moisture issues. Fiberglass batts, for example, are excellent insulators but are terrible air barriers on their own. Air sealing creates the “windbreaker” that allows your insulation “sweater” to perform at its best.

Can I make my house too airtight?

This is a valid concern, especially with modern construction focused on airtightness. While the goal of air sealing basement areas is to reduce uncontrolled air leakage, it’s possible to make a house too airtight without proper consideration for ventilation.

- The Risks: If a home becomes excessively airtight without adequate mechanical ventilation, several issues can arise:

- Combustion Appliance Safety: As discussed earlier, atmospherically vented combustion appliances can backdraft carbon monoxide.

- Indoor Air Quality: Without fresh air exchange, indoor pollutants (VOCs from building materials, cooking fumes, pet dander, etc.) and excess humidity can build up, leading to poor indoor air quality, potential mold growth, and respiratory issues.

- Moisture Buildup: Trapped moisture can lead to condensation problems within wall cavities and on surfaces.

- The Solution: Controlled Ventilation: Modern, airtight homes require controlled mechanical ventilation systems (like exhaust fans or heat recovery ventilators, HRVs) to ensure a continuous supply of fresh air while minimizing energy loss. The key is to control where and how much air enters and leaves your home, rather than letting it happen indiscriminately through leaks. When we perform extensive air sealing, especially in an entire home, we always discuss ventilation strategies to maintain a healthy indoor environment.

When should I hire a professional for my air sealing basement project?

While a DIY enthusiast can tackle minor air sealing basement tasks, hiring a professional like ClimaShield Spray Foam is recommended or necessary in several situations:

- Significant Energy Loss or Comfort Issues: If you’re experiencing persistent cold spots, high energy bills (20-40% higher than average for your area), or a consistently uncomfortable basement, a professional energy audit with a blower-door test is invaluable. We can precisely locate hidden leaks and recommend the most effective solutions.

- Complex or Extensive Leaks: If your basement has numerous or large leaks, or if you have an older home with irregular foundation walls (like stone or rubble), the project can become quite involved. Our expertise ensures these challenging areas are sealed correctly and durably.

- Combustion Appliance Concerns: If you have atmospherically vented furnaces, water heaters, or other combustion appliances in your basement, professional assessment and post-sealing combustion-safety testing are crucial to prevent dangerous backdrafting.

- Radon Concerns: If radon testing reveals high levels, a professional radon mitigation contractor should be involved. Air sealing can be part of the solution, but a comprehensive approach is needed.

- Moisture or Mold Issues: Existing moisture intrusion or mold growth demands professional remediation before any air sealing or insulation work begins. Sealing over these problems will only make them worse.

- Specialized Materials and Equipment: Applying spray foam effectively and safely requires specialized equipment and training. DIY kits are available for small areas, but for larger projects, professional application ensures consistent coverage, proper expansion, and optimal performance.

- Long-Term Durability and Guarantees: As professionals, we offer warranties on our work, giving you peace of mind that your investment in air sealing basement will last. The interaction between air sealing, insulation, and mechanical/ventilation equipment, as well as durability considerations, often requires trained professionals to ensure everything works together as a system.

For simple, obvious leaks that are easily accessible, a homeowner can certainly tackle them. But for a truly comprehensive, safe, and effective air sealing basement solution that maximizes energy savings and comfort, we recommend consulting with our experts at ClimaShield Spray Foam.

Conclusion: A More Comfortable and Efficient Home Awaits

Investing in air sealing basement areas is one of the most impactful improvements you can make to your Pennsylvania home. By stopping the “chimney effect” at its source, you’ll immediately notice a difference in comfort throughout your entire house – no more cold floors, drafts, or uneven temperatures.

Beyond comfort, the financial benefits are significant. Our clients often report cutting their energy use by as much as 20-40%, leading to substantial long-term savings on heating and cooling bills. Plus, our durable, waterproof, and airtight spray foam insulation resists mold and pests, contributing to improved indoor air quality and a healthier home environment for your family.

At ClimaShield Spray Foam, we combine our 20 years of experience with the latest spray foam technology to deliver superior results. We understand the unique challenges of Pennsylvania’s climate and older homes, and we’re committed to providing solutions that offer lasting comfort, energy efficiency, and peace of mind.

Ready to breathe easier and save money? Learn more about the many uses of spray foam and find how we can transform your basement into a comfortable, energy-efficient part of your home.