Why Mold Growth is a Critical Concern for Homeowners

Is spray foam insulation mold resistant? Yes, closed-cell spray foam insulation is highly mold resistant because it creates a waterproof, airtight barrier that eliminates the moisture mold needs to grow. Unlike traditional insulation materials that can trap and absorb water, closed-cell spray foam repels moisture and provides no organic food source for mold. However, proper installation is critical, and any existing mold must be remediated before application.

Key Facts:

- Closed-cell spray foam is hydrophobic and does not absorb water

- Mold cannot grow directly on the foam itself due to its inert polymer composition

- Acts as a Class II vapor retarder at 1.5-2 inches thickness

- Open-cell spray foam can absorb water and is not recommended for moisture-prone areas

- Professional installation is essential to maximize mold-prevention properties

That musty smell in your basement isn’t just unpleasant—it’s a warning sign. Mold is a silent threat that can develop on damp surfaces within just 24 to 48 hours, causing respiratory problems, structural damage, and expensive repairs. The root cause is always the same: moisture.

Traditional insulation materials like fiberglass and cellulose act like sponges, trapping and holding water. This creates the perfect breeding ground for mold, especially in high-risk areas like basements, crawl spaces, and attics. These older materials weren’t designed to handle moisture, which is why so many homes struggle with recurring mold problems despite repeated remediation efforts.

Modern spray foam insulation takes a different approach. Instead of just covering your walls, it actively prevents mold by eliminating the moisture that feeds it. Closed-cell spray foam creates a seamless barrier that blocks water intrusion, seals out humid air, and starves mold of the conditions it needs to survive.

I’m Dave Brocious, and with 20 years in the coatings industry and as the founder of ClimaShield Industries, I’ve seen how is spray foam insulation mold resistant properties transform homes plagued by moisture issues into healthy, energy-efficient spaces. Understanding how spray foam prevents mold starts with understanding what mold needs to grow.

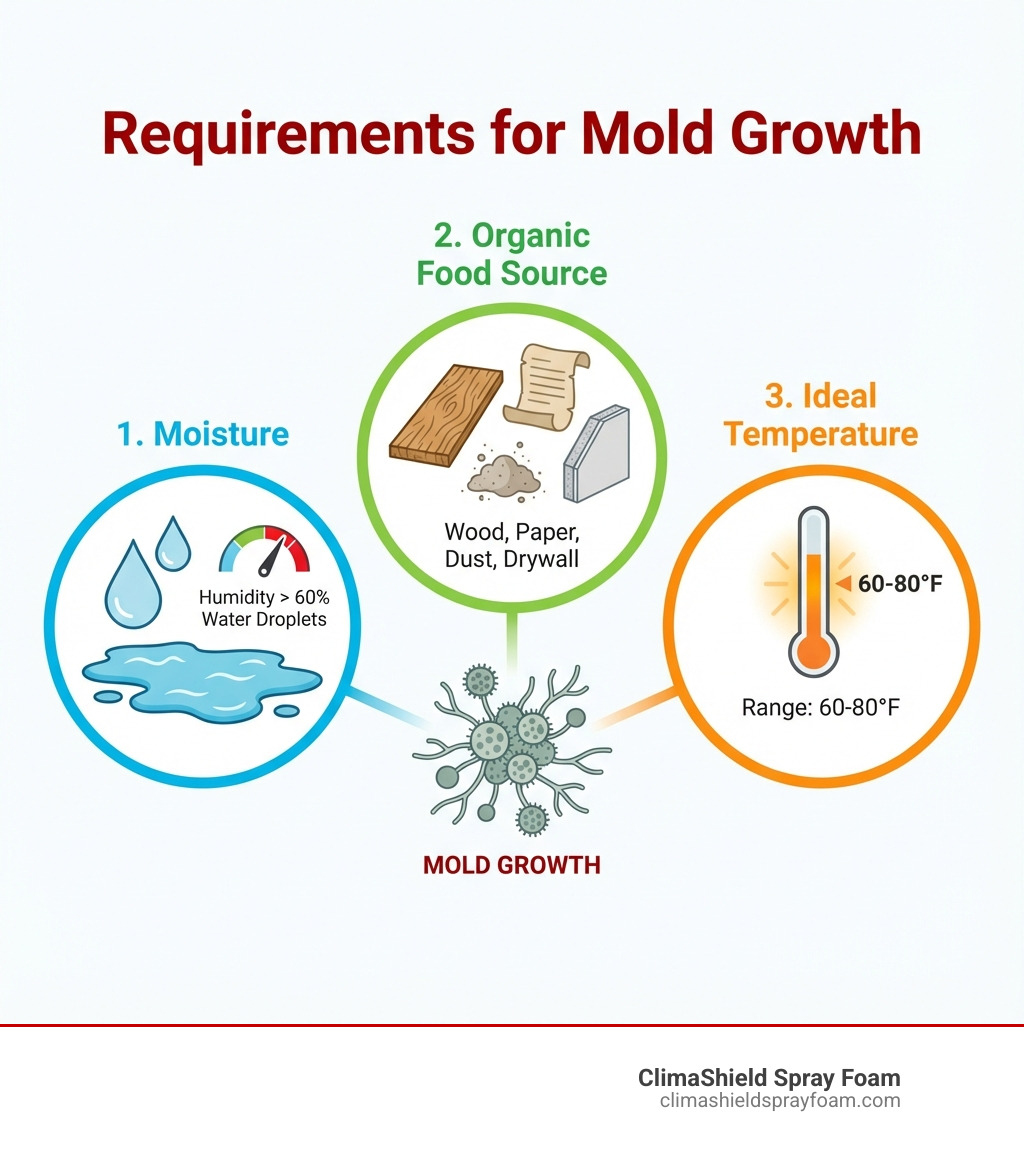

Understanding the Enemy: What Mold Needs to Thrive

Before we can effectively fight mold, we need to understand what it needs to survive and thrive. Think of mold as an unwelcome houseguest with very specific demands. If you cut off its supply, it can’t stick around. Mold requires three primary conditions to grow indoors:

-

Moisture: This is the absolute non-negotiable. Mold cannot grow without water. This moisture can come from various sources:

- High Relative Humidity: When indoor relative humidity consistently stays above 60%, the risk of mold growth dramatically increases. The air gets so saturated with moisture that it starts to condense on cooler surfaces.

- Condensation: This occurs when warm, moist air comes into contact with a cold surface. Think of the inside of a window on a cold day, or a sweating pipe in a humid basement. These damp spots are prime locations for mold.

- Bulk Water Intrusion: Leaky roofs, plumbing failures, foundation cracks, or even improper drainage around your home can introduce significant amounts of water into your building envelope.

- Porous Surfaces: Materials like drywall, wood, carpeting, and yes, many traditional insulation types, readily absorb and hold moisture, providing a perfect damp environment for mold spores to germinate.

-

Organic Food Source: Mold isn’t picky; it loves to munch on pretty much any organic material commonly found in homes. This includes wood, paper (like on drywall), dust, fabrics, and even dirt. Crucially, many traditional insulation materials, such as cellulose (made from recycled paper products) or fiberglass (which can trap organic dust and debris), offer abundant food sources once they get damp.

-

Ideal Temperature Range: While mold can survive in a wide range of temperatures, it truly thrives in conditions that are comfortable for us, typically between 60–80°F (15–27°C). This is why our homes, especially in areas like Pennsylvania, often provide the perfect warm and damp environment for mold colonies to flourish.

The insidious thing about mold is how quickly it can take hold. Indoor mold can begin developing on damp surfaces within a mere 24 to 48 hours. This rapid onset means that even a small, undetected leak or a persistent humidity problem can quickly escalate into a significant mold issue.

Traditional insulation materials often worsen these problems. Fiberglass batts trap moisture and organic particles, creating a haven for mold. Cellulose insulation, being paper-based, is even more vulnerable as it provides a direct food source once damp. These materials act like sponges, holding moisture against your home’s structure. This is why a solution that actively tackles moisture is necessary.

How Spray Foam Creates a Mold-Resistant Environment

At ClimaShield Spray Foam, we know true mold prevention means creating an environment where mold cannot exist. Closed-cell spray foam insulation excels at this. It’s a comprehensive building envelope solution that proactively eliminates the conditions for mold growth.

Our durable, waterproof, and airtight insulation works on multiple fronts to defend your home against mold:

- Air Sealing: It creates a seamless barrier that stops air leakage, preventing humid air from entering wall cavities and leading to condensation.

- Moisture Barrier: Its dense, closed-cell structure actively repels water, acting as a powerful moisture and even a vapor barrier.

- Inert Polymer Composition: Unlike organic materials, our spray foam provides no food source for mold or mildew.

- Condensation Prevention: By sealing air and controlling temperature, it prevents the formation of condensation on surfaces, which is a primary cause of mold.

- Structural Reinforcement: The rigid nature of closed-cell spray foam can actually add structural strength to your walls and roof deck, enhancing your home’s resilience.

- Improved Air Quality: By blocking air infiltration, it reduces the entry of outdoor allergens, pollutants, and mold spores, leading to a healthier indoor environment.

- Energy Savings: As a bonus, this superior thermal envelope can reduce heating and cooling costs by up to 40%. You can learn more about how we help reduce your energy bills on our Your Energy Bill page.

Let’s dig deeper into how these properties make closed-cell spray foam your home’s champion defender against mold.

Eliminating Moisture: The Power of a Waterproof Shield

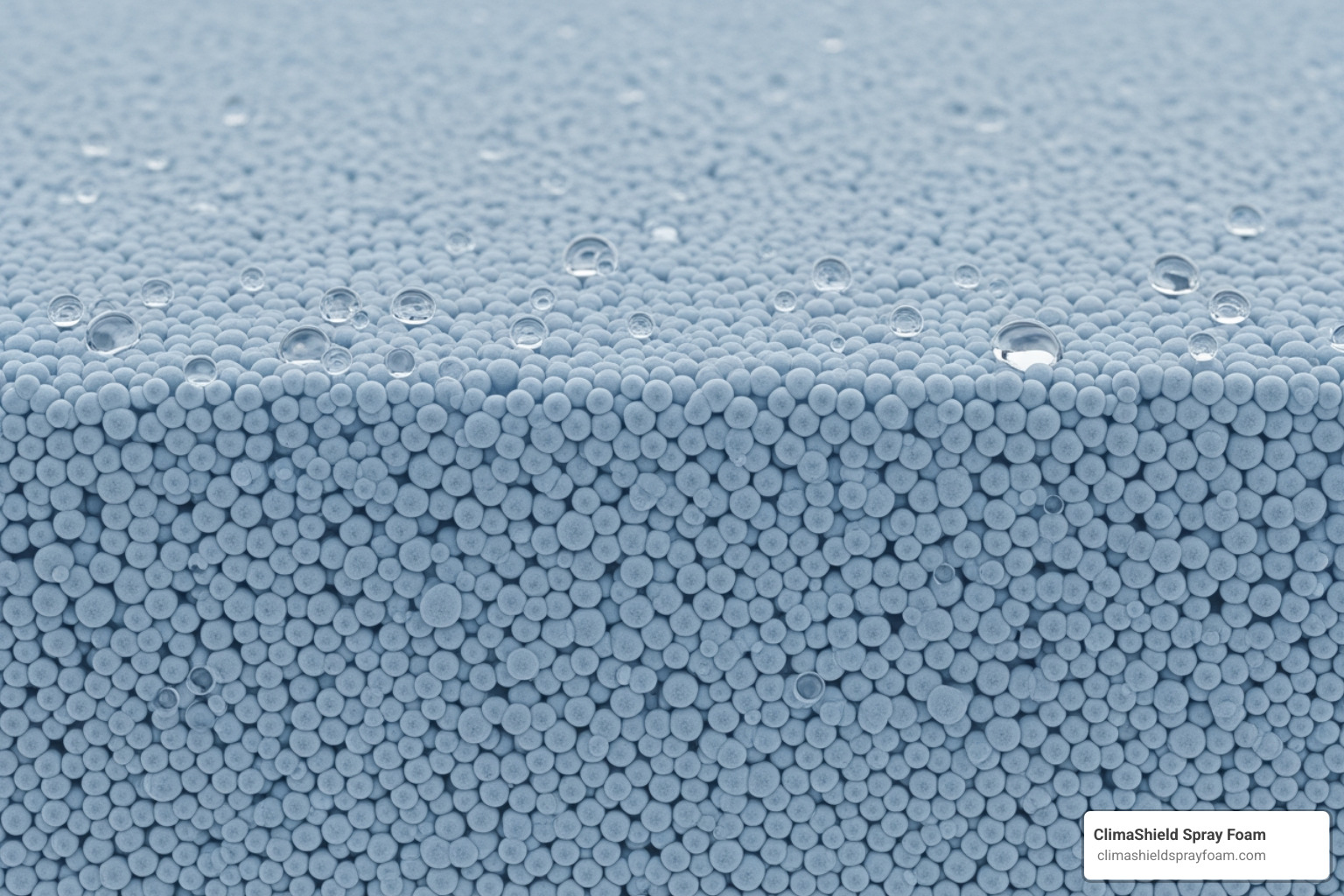

Moisture control is the most critical factor in mold prevention, and closed-cell spray foam excels with its hydrophobic properties. It provides a seamless, rigid raincoat for your home’s structure.

Unlike traditional insulation that can absorb and hold water like a sponge, closed-cell foam is inherently hydrophobic – meaning it repels water. Its dense, enclosed cell structure means that water molecules simply cannot penetrate or be absorbed into the material. This makes it an incredibly effective moisture barrier, blocking water from entering walls, crawl spaces, or attics. When there’s no excess moisture, mold has no chance to grow.

This impermeability is crucial for protecting your home’s structural integrity. By preventing moisture intrusion, closed-cell spray foam helps prevent issues like wood rot and the corrosion of fasteners, which can severely compromise a building over time. Our insulation isn’t just keeping your home warm; it’s actively keeping it dry and structurally sound.

Stopping Condensation by Creating an Air Seal

Condensation is a primary cause of mold, often leading to hidden problems within walls and attics. It occurs when warm, humid air contacts a cold surface, causing moisture to condense into water. This is a battle traditional insulation often loses.

Closed-cell spray foam tackles condensation head-on by creating an unparalleled air seal. It expands to fill every crack, crevice, and void, effectively eliminating the tiny pathways through which humid air infiltrates your building envelope. By stopping this uncontrolled air movement, we prevent warm, moist indoor air from reaching cold exterior sheathing or framing in your walls and attics.

This means we can eliminate the “dew point” on surfaces inside your building assemblies. No more humid air condensing on cold surfaces, no more damp spots, and thus, no breeding ground for mold. This is particularly vital in areas like attics, where uncontrolled warm air can lead to “attic rain” – condensation forming on the underside of the roof deck. Similarly, in basements, our spray foam prevents condensation from forming on cold concrete walls, a common source of that dreaded musty smell. By blocking humid air movement, we effectively cut off one of mold’s favorite water sources.

Starving Mold: An Inert Material with No Food Value

Beyond moisture control, closed-cell spray foam delivers another powerful blow to mold: it provides no food source. Mold needs organic materials like wood, paper, and dust to survive, but our inert plastic polymer offers nothing for it to consume.

Our closed-cell spray foam is an inert plastic polymer. This means its chemical composition does not contain any organic materials that mold, mildew, or bacteria can feed on. Mold simply cannot grow directly on the foam itself because there’s nothing for it to consume.

This is a significant advantage over traditional insulation types. Fiberglass, while not organic itself, is often riddled with trapped dust and dirt—which are organic and can become a mold food source when damp. Cellulose, being paper-based, is an organic feast for mold once moisture is introduced. With spray foam, we eliminate this crucial element of mold’s survival equation, making your home a much less hospitable place for these unwelcome guests. Furthermore, by creating such an effective air seal, our insulation helps to reduce the accumulation of dust and other airborne organic particles within your wall cavities, further depriving mold of potential nourishment.

Open-Cell vs. Closed-Cell: Which Is Better for Mold Prevention?

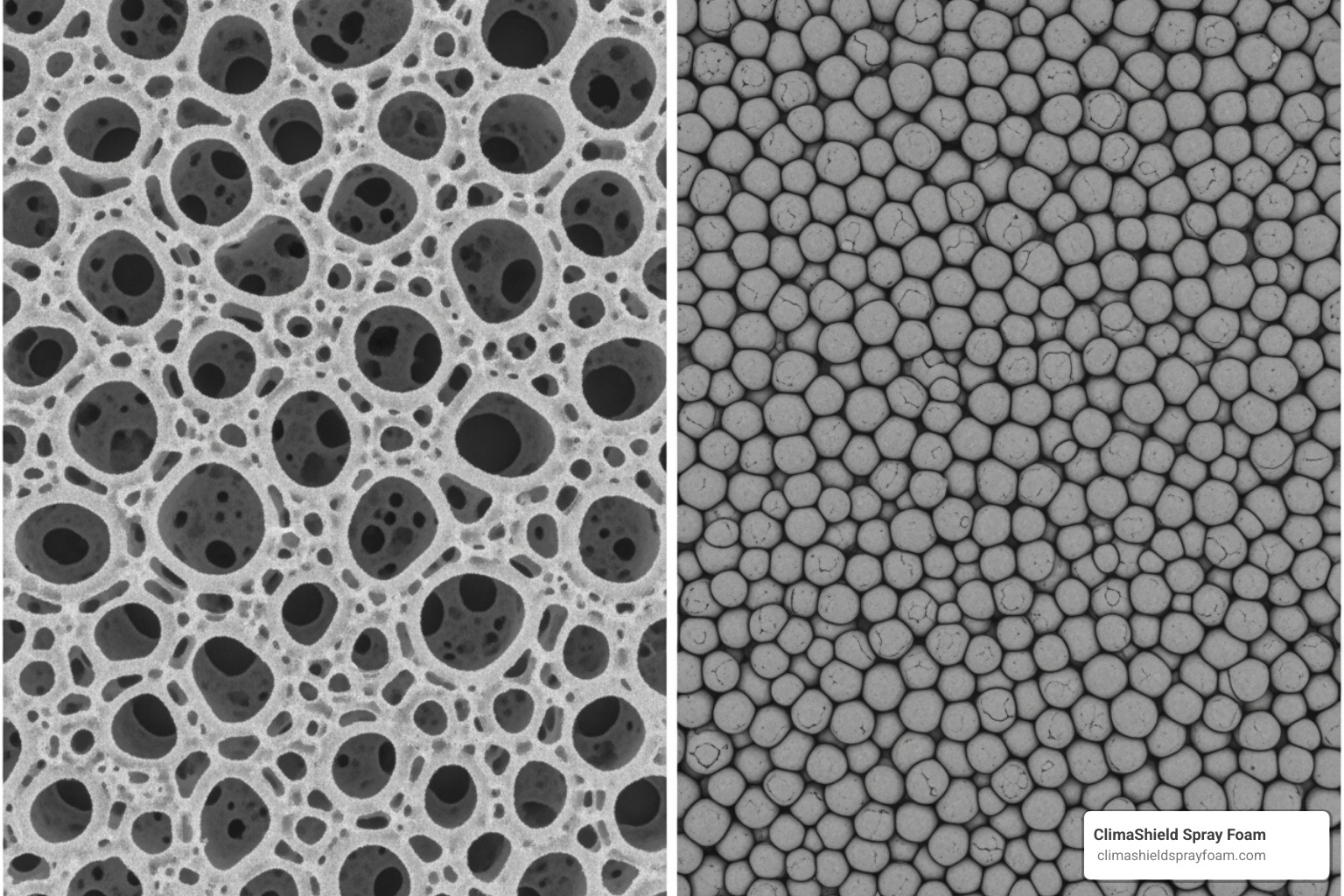

When discussing spray foam insulation, it’s crucial to distinguish between its two main types: open-cell and closed-cell. While both offer superior air-sealing properties compared to traditional insulation, their differing structures have a significant impact on their moisture resistance and, consequently, their effectiveness in preventing mold.

Let’s break down the key differences:

| Feature | Open-Cell Spray Foam | Closed-Cell Spray Foam |

|---|---|---|

| R-Value | ~3.6 per inch | ~6.0-7.0 per inch |

| Water Absorption | Can absorb up to one-third by volume, holds water | Hydrophobic, will not absorb or retain moisture |

| Air Permeability | Air-impermeable at sufficient thickness | Air-impermeable at sufficient thickness |

| Vapor Permeability | High (around 10 perms), vapor-permeable | Low (<1 perm at ~2 inches), Class II vapor retarder |

| Structural Rigidity | Softer, flexible, no structural contribution | Rigid, dense, adds structural strength |

Why is Closed-Cell Spray Foam Insulation Mold Resistant?

For mold prevention, closed-cell spray foam is the clear champion. Its unique properties create an environment where mold struggles to survive:

- Dense Cell Structure: The individual cells within closed-cell foam are sealed and packed tightly together. This dense structure is what makes it highly resistant to water penetration. It’s essentially a solid barrier.

- Low Vapor Permeance: At a typical thickness of around 1.5 to 2 inches, closed-cell spray foam achieves a vapor permeance of less than 1 perm. This means it significantly restricts the movement of water vapor, effectively acting as a Class II vapor retarder. This is a major advantage, as it often eliminates the need for a separate vapor barrier, simplifying construction and reducing potential points of failure.

- Blocks Moisture Intrusion: Because it’s hydrophobic and doesn’t absorb water, closed-cell foam blocks bulk water from entering your wall cavities or other building assemblies. This direct moisture resistance is paramount in preventing mold.

- Adds Structural Strength: Beyond insulation and moisture control, the rigidity of closed-cell spray foam can actually add racking strength to your walls and roof decks, a valuable benefit for the longevity and durability of your home.

- Ideal for Below-Grade Applications: Due to its water-tolerant and resistant nature, closed-cell SPF is the preferred and often only recommended type for insulating foundations, basements, and crawl spaces. These are notoriously damp areas where open-cell foam would be a liability. Whether it’s for a residential basement or a large-scale Commercial Insulation project, closed-cell foam offers robust protection.

When we talk about is spray foam insulation mold resistant, we are primarily referring to the exceptional capabilities of closed-cell spray foam.

When to Be Cautious with Open-Cell Foam

While open-cell spray foam is an excellent air barrier and offers good thermal performance in certain applications, it comes with significant caveats when mold prevention is a top priority, especially in moisture-prone areas.

- Spongy Texture and High Vapor Permeance: Open-cell foam has a softer, more flexible, and spongy texture because its cells are interconnected and open. This structure makes it highly vapor-permeable (around 10 perms), meaning water vapor can easily pass through it.

- Can Absorb and Hold Water: The biggest concern for mold is that open-cell foam can absorb and hold a significant amount of water, up to one-third of its volume. If a leak occurs, or if it’s installed in a humid environment without proper vapor control, it can become saturated. Once saturated, it acts like a giant sponge within your walls, creating the ideal damp, dark conditions for mold to flourish.

- Risk of Moisture Trapping: Because it can hold water, open-cell foam can potentially trap moisture against your home’s structure, leading to wood rot and hidden mold growth if the source of moisture isn’t addressed and the foam isn’t allowed to dry out.

- Not a Vapor Barrier: Unlike closed-cell foam, open-cell foam is generally not considered a vapor barrier and often requires a separate vapor retarder in colder climates like Pennsylvania to prevent moisture from migrating through the insulation and condensing on cold surfaces.

- Unsuitable for Basements or Crawl Spaces: Due to its moisture-absorbent nature, open-cell foam is generally not recommended for below-grade applications like basements and crawl spaces, where moisture is almost always a concern.

While open-cell foam has its place, particularly in drier, above-grade applications where its sound-dampening properties are valued, we exercise caution and often recommend closed-cell foam in areas where mold resistance is paramount.

So, Is Spray Foam Insulation Mold Resistant in Your Home?

The short answer is a resounding “yes,” particularly when referring to closed-cell spray foam. However, this isn’t a magic bullet. The effectiveness of spray foam in preventing mold hinges on two critical factors: proper application and addressing any existing moisture issues before installation.

At ClimaShield Spray Foam, we don’t just spray and go. We conduct a thorough assessment of your property in Pennsylvania to identify any existing mold or moisture problems. If mold is present, we will always recommend professional remediation first. Spray foam is a preventative measure for future mold, not a cure for current infestations.

Once your home is ready, our professional installation ensures that the spray foam’s mold-resistant properties are maximized. This means a seamless, airtight, and moisture-resistant barrier that will protect your home and family for decades to come, contributing to long-term home health and comfort.

Best Applications: Where is Spray Foam Insulation Mold Resistant?

While spray foam insulation can benefit virtually any area of your home, certain zones are particularly vulnerable to moisture and mold. These are the areas where the mold-resistant properties of closed-cell spray foam truly make a difference:

- Basements: These are often the dampest parts of a home, prone to condensation on cold concrete walls and potential moisture intrusion from the ground. Closed-cell spray foam applied to interior basement walls creates a thermal, air, and moisture barrier, preventing condensation and helping to keep the space dry and mold-free.

- Crawl Spaces: Unsealed and poorly ventilated crawl spaces are notorious for ground moisture, high humidity, and poor air quality, making them prime mold habitats. Encapsulating a crawl space with closed-cell spray foam locks out ground moisture and humidity, changing it into a dry, conditioned space.

- Attics and Roof Decks: Attics can suffer from “attic rain” due to warm, moist indoor air condensing on cold roof sheathing. Spraying closed-cell foam directly to the underside of the roof deck creates an unvented, conditioned attic space, eliminating condensation and preventing mold growth on the wood.

- Rim Joists: These are the perimeter boards connecting your foundation to your floor joists, often overlooked but major sources of air leakage and moisture entry. Sealing rim joists with closed-cell spray foam creates an airtight and moisture-resistant barrier, preventing mold in this critical transition area.

- Walls in Bathrooms and Kitchens: Areas with high levels of steam and vapor, like bathrooms and kitchens, are constantly challenging for moisture control. Insulating these wall cavities with closed-cell spray foam helps to prevent condensation within the walls, keeping them dry and preventing mold from forming behind tiles or paint.

In all these high-moisture zones, the combination of air sealing, moisture resistance, and inert composition makes closed-cell spray foam an unparalleled solution for mold prevention. It’s a key component of our Residential Insulation services, designed to create healthier, more energy-efficient homes in Pennsylvania.

The Critical Role of Professional Installation

We can’t stress this enough: the mold-resistant properties of spray foam are only fully realized with professional installation. DIY kits carry significant risks of installation errors that can undermine the foam’s performance and even lead to moisture issues if done incorrectly.

What can go wrong with improper installation?

- Off-Ratio Mixtures: Spray foam is created on-site by mixing two chemical components. If these components are not mixed in the correct “off-ratio,” the foam may not cure properly. This can lead to a soft, unstable product that shrinks, pulls away from surfaces, or even emits a persistent, bad odor. A poorly cured foam won’t provide the expected air or moisture barrier, potentially leading to mold.

- Gaps and Cracks: If the foam isn’t applied consistently or doesn’t fully expand to fill all voids, tiny gaps and cracks can remain. These seemingly small imperfections can still allow air and moisture to infiltrate, creating pathways for condensation and mold growth.

- Improper Surface Preparation: Surfaces must be clean, dry, and at the correct temperature for the foam to adhere properly. If not, the foam may delaminate or not form a complete seal, compromising its effectiveness.

- Environmental Conditions: Spray foam needs to be applied in suitable environmental conditions, avoiding extreme humidity or temperatures, for optimal curing. Professionals monitor these variables closely.

At ClimaShield Spray Foam, our certified technicians have the expertise and specialized equipment to ensure every installation is flawless. We guarantee the correct thickness, complete coverage, and proper curing to maximize mold resistance and energy efficiency. This professional touch is the difference between a successful solution and a potential headache. For comprehensive guidance, you can refer to resources like the GM-2102: Residential Spray Foam Guide.

Frequently Asked Questions about Spray Foam and Mold

We often encounter common questions about spray foam and its relationship with mold. Here are some of the most frequent inquiries we receive:

Can mold grow directly on spray foam insulation?

No, mold cannot grow directly on closed-cell spray foam. It is an inert plastic polymer that provides no organic food source and does not absorb moisture. However, mold can grow on dirt or dust that accumulates on the foam’s surface if it gets wet from an external source, like a leak. This is not the foam molding, but the debris on it. A professional installation helps reduce this risk by creating a well-sealed building envelope.

Do I need to remove existing mold before installing spray foam?

Yes, absolutely. Spray foam prevents future mold growth but is not a solution for existing mold. Any current mold must be professionally remediated before insulation is installed. Spraying over mold will only trap it, not remove it or its spores. Proper remediation, which can cost from $5,000 to $10,000, is critical for a healthy home and ensures our spray foam provides a clean start for your home’s long-term health.

Does closed-cell spray foam replace the need for a separate vapor barrier?

Yes, in most applications. When applied at the correct thickness (typically 1.5 to 2 inches), closed-cell spray foam acts as an all-in-one insulator, air seal, and Class II vapor retarder. Its low vapor permeance (less than 1 perm at ~2 inches) eliminates the need for a separate vapor barrier, simplifying construction and reducing potential errors. In Pennsylvania’s climate, this thickness is generally sufficient to meet building code requirements for vapor control.

Your Best Defense for a Healthy, Mold-Free Home

Choosing the right insulation is critical for a healthy, mold-free home. As we’ve explored, closed-cell spray foam is a highly effective, proactive solution for homeowners in Pennsylvania. It systematically eliminates the conditions mold needs to thrive by repelling moisture, creating an air seal to prevent condensation, and offering no food source. This combination makes it an unparalleled defense against mold, rot, and associated health risks.

Choosing spray foam is an investment in your home’s structure, your family’s health, and your energy savings. However, its effectiveness hinges on expert application. At ClimaShield Spray Foam, our commitment is to provide precise, professional installation to ensure your home is protected. Don’t let mold compromise your peace of mind. Let us help you create a healthier, more comfortable home. To learn more, explore our Uses of Spray Foam page.