Why Your Building’s Thermal Envelope is the Foundation of Energy Efficiency

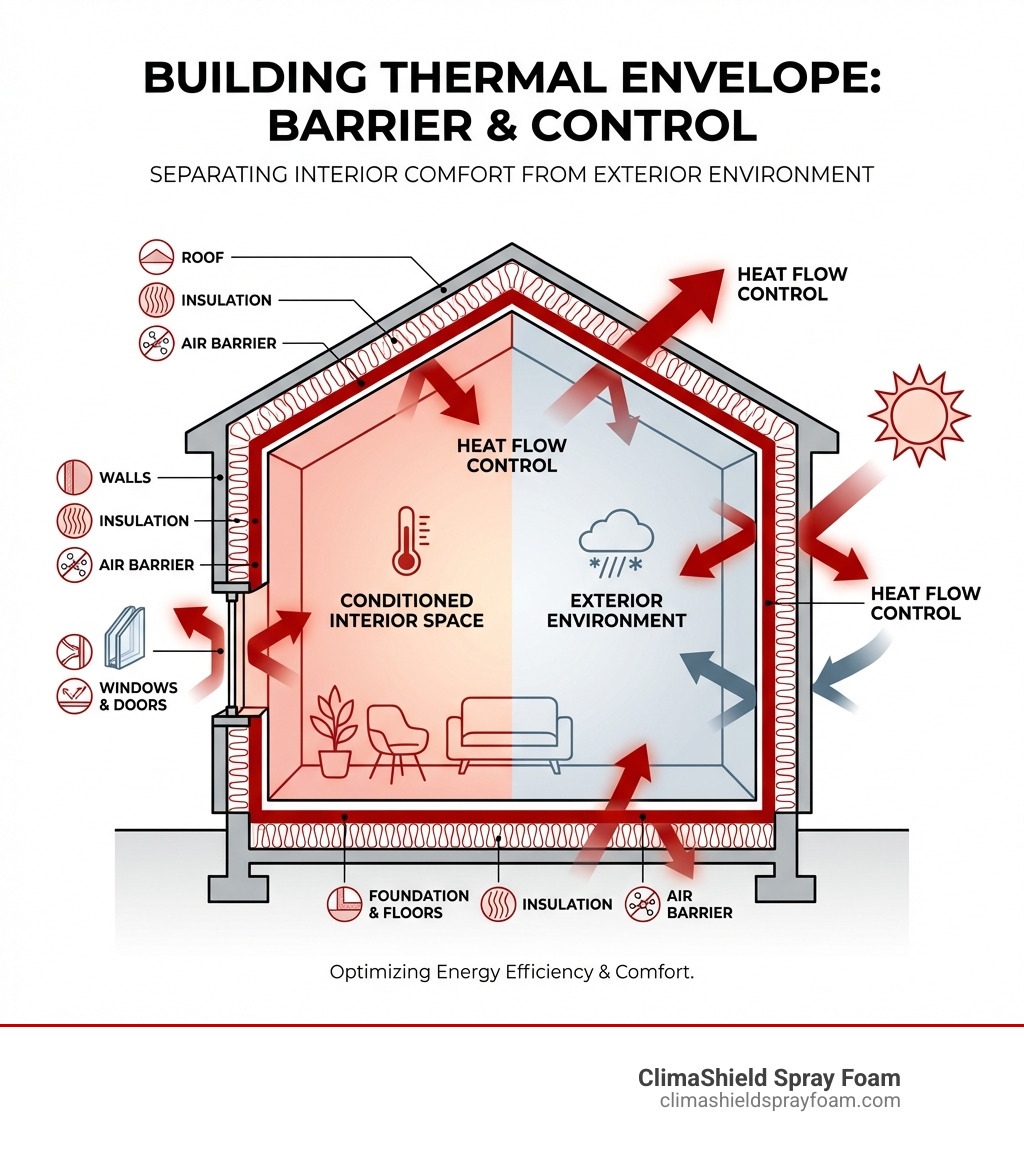

A building thermal envelope is the physical barrier that separates the interior conditioned space from the exterior environment, controlling the flow of heat, air, and moisture. It includes all the components that form this boundary—walls, roofs, floors, foundations, windows, and doors—working together like a warm coat wrapped around your home or commercial building.

Key Components of a Building Thermal Envelope:

- Walls and Roofs – Primary barriers between inside and outside

- Insulation – Reduces heat transfer through the envelope

- Air Barriers – Prevents unwanted air leakage (infiltration and exfiltration)

- Windows and Doors – Transparent and opaque openings that must be sealed and insulated

- Foundation and Floors – Below-grade and base components that separate conditioned from unconditioned space

Why It Matters:

- Controls up to 40% of your heating and cooling costs (air infiltration alone)

- Determines occupant comfort by eliminating drafts and temperature fluctuations

- Protects building durability by managing moisture and preventing condensation

- Reduces energy consumption and lowers utility bills

A “tight” thermal envelope minimizes heat loss and drafts, keeping your space comfortable year-round while slashing energy costs. A “loose” envelope, on the other hand, lets conditioned air escape freely—essentially heating or cooling the outdoors while your utility bills soar.

I’m Dave Brocious, and with 20 years of experience in specialty coatings and building envelope solutions—including spray foam insulation, air barrier coatings, and waterproofing—I’ve seen how a properly designed building thermal envelope transforms energy efficiency and comfort. At ClimaShield Spray Foam, we specialize in creating high-performance thermal envelopes that deliver long-term savings and protection.

What is a Building’s Thermal Envelope?

At its core, a building thermal envelope is “everything about the house that serves to shield the living space from the outdoors,” as described by The National Renewable Energy Laboratory. Think of it as the protective shell of your structure, the heat flow control layer that dictates how much energy you need to maintain comfortable indoor temperatures. It’s the physical separation, the barrier between your cozy interior and the sometimes harsh exterior environment.

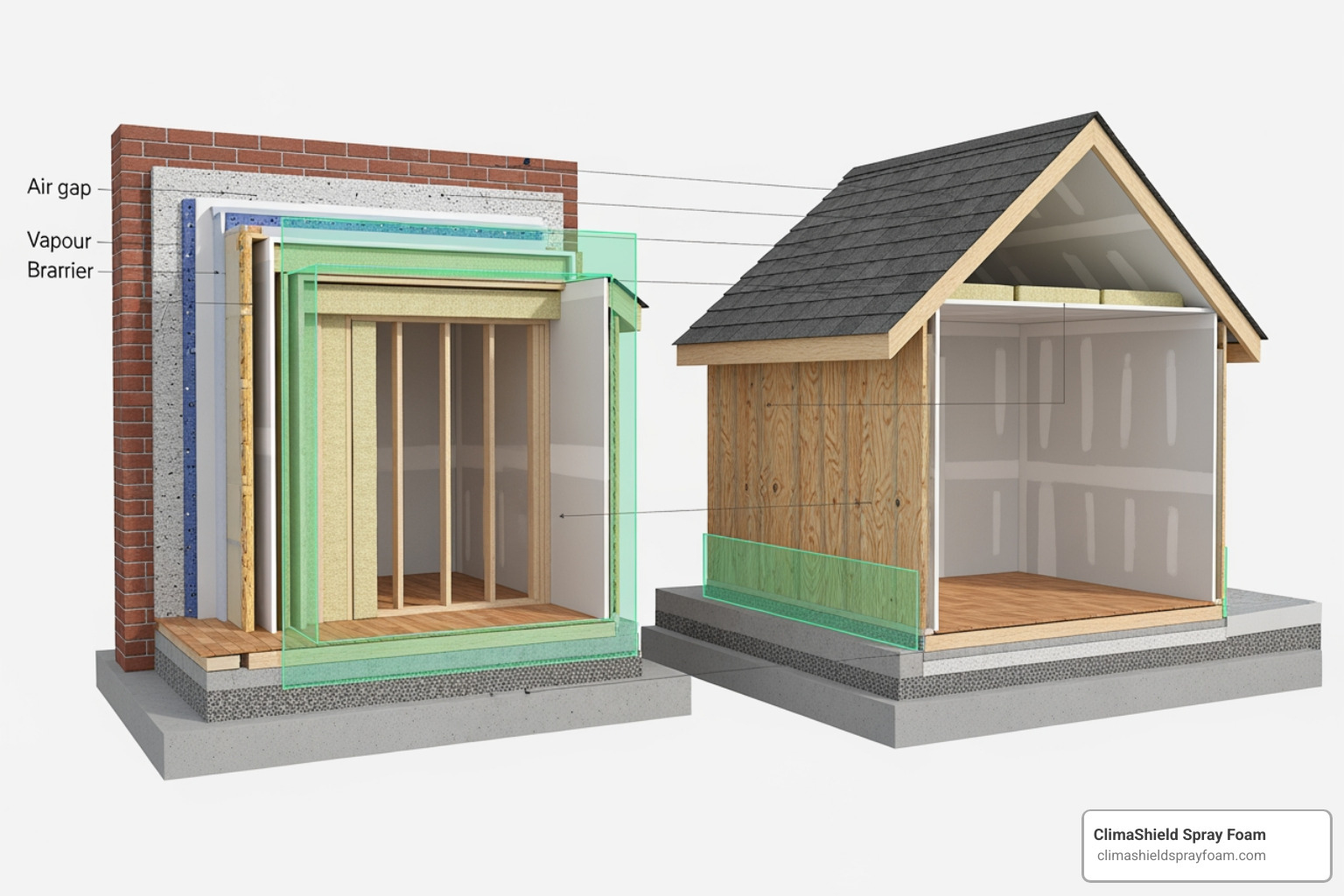

This critical barrier includes a variety of components: the wall and roof assemblies, insulation, air and vapor retarders, windows, doors, and even the weatherstripping and caulking that seal those openings. It’s a complex system, made up of both opaque parts (like walls, roofs, and floors) and transparent parts (such as windows, skylights, and glass doors). Every single element plays a role in its overall performance.

Defining the Boundary: Conditioned vs. Unconditioned Space

One of the most important aspects of understanding your building’s thermal envelope is recognizing the difference between conditioned and unconditioned spaces. A conditioned space is any part of your building that is intentionally heated or cooled for occupant comfort. This includes living rooms, bedrooms, kitchens, offices, and any other habitable areas. These are the spaces we want to keep at a consistent, comfortable temperature, regardless of what’s happening outside.

In contrast, non-conditioned spaces are those areas that are not actively heated or cooled. This might include uninsulated garages, attics where the insulation is located above the ceiling, porches, or vented crawlspaces. The thermal envelope’s job is to create a continuous, unbroken boundary between these two types of spaces.

For example, the International Energy Conservation Code (IECC), which influences building codes across the country, including in Pennsylvania, defines the thermal envelope as encompassing “basement walls, exterior walls, floors, roofs, and any other building element enclosing the conditioned space.” This boundary exists wherever a conditioned space meets an unconditioned space or the outdoors. Getting this boundary right is fundamental to controlling energy flow.

Tight vs. Loose Envelopes

The effectiveness of a thermal envelope can often be described as either “tight” or “loose,” and this distinction has a massive impact on your energy bills and comfort.

A tight thermal envelope means your building is well-sealed and insulated, minimizing unwanted air leakage and heat transfer. This creates a highly efficient space that won’t lose much heating or cooling. The result? Reduced drafts, consistent indoor temperatures, and significant savings on Your Energy Bill. For us at ClimaShield, achieving a tight envelope is a cornerstone of our work, contributing directly to the high Energy Efficiency our clients experience.

On the flip side, a loose thermal envelope is like trying to keep warm in a coat full of holes. It results in a drafty home or office, allowing conditioned air to escape and unconditioned air to infiltrate freely. This dramatically increases the effort your HVAC system needs to maintain comfort, leading to sky-high utility bills. In fact, studies show that air infiltration alone can account for up to 40% of the heating and cooling load in houses. That’s a lot of energy—and money—simply escaping through cracks and gaps!

Why a High-Performance Thermal Envelope is Crucial

Investing in a well-designed, high-performance building thermal envelope isn’t just about making your space feel nicer; it’s about making a smart, long-term investment in energy savings, comfort, and even the durability of your building.

Energy Savings

The most immediate and tangible benefit of a superior thermal envelope is the drastic reduction in energy consumption. By minimizing heat transfer and air leakage, your heating and cooling systems don’t have to work as hard. This directly translates into lower utility bills, year after year. Our clients in Indiana, PA, and across Pennsylvania consistently see the results of this efficiency, often experiencing significant reductions in their energy costs. It’s a foundational step towards reducing your environmental footprint and limiting CO2 emissions, contributing to broader energy goals without sacrificing comfort.

Occupant Comfort

Imagine a home or office where every room maintains a consistent, comfortable temperature, free from cold drafts in the winter or hot spots in the summer. That’s the promise of a high-performance thermal envelope. It ensures that the inside environment is protected from adverse external conditions, providing a stable and pleasant indoor climate. When we seal and insulate a building effectively, we’re not just saving energy; we’re creating spaces where people feel truly comfortable and productive.

Building Durability

Beyond comfort and cost, a robust thermal envelope plays a vital role in the longevity and health of your building. By controlling moisture movement and preventing condensation within wall cavities and roof assemblies, it helps to mitigate issues like mold growth, wood rot, and structural degradation. Components like vapor retarders are crucial here, inhibiting the movement of moisture that can compromise insulation performance and building materials over time. This proactive approach to moisture management protects your investment and maintains the structural integrity of your property for decades to come.

The Impact of Building Design and Compactness

The very shape of a building can significantly influence its thermal performance, a concept often described by its compactness factor. This factor is defined as the ratio of a building’s volume to its outer surface area.

A notably compact building is one that has a high volume-to-surface ratio. Think of a cube or a sphere – these shapes minimize the amount of exterior surface exposed to the elements relative to the interior space they enclose. With less surface area, there are fewer opportunities for heat to escape or enter, making the building inherently more energy-efficient. This also contributes to the building’s heat storing capacity, helping it to maintain stable indoor temperatures.

Conversely, a building with a low compactness factor, perhaps one with many complex angles, protrusions, or wings, will have a larger surface area relative to its volume. This increased exposure means more pathways for heat loss or gain, demanding more from the thermal envelope to maintain comfort. While architectural aesthetics are important, considering compactness during the design phase is a simple yet powerful way to lay the groundwork for an energy-efficient structure from day one.

Key Components and Performance Metrics of a Building Thermal Envelope

The effectiveness of your building thermal envelope hinges on the quality and interplay of its core components and how we measure their performance.

Insulation

Insulation is the unsung hero of the thermal envelope, acting as the primary barrier against heat flow. Its ability to resist heat transfer is measured by its R-value (thermal resistance). A higher R-value indicates better insulating power. From traditional fiberglass to advanced spray foam, each material offers different R-values and application benefits. At ClimaShield, we often recommend spray foam for its superior performance, which we detail in our Residential Insulation services, because it creates a seamless, high-R-value layer.

Airtightness

Beyond insulation, preventing uncontrolled air movement is paramount. Airtightness refers to how well your building prevents air from leaking in or out. Air barriers, such as specialized membranes or, crucially, spray foam, are installed to create a continuous seal, eliminating drafts and preventing energy loss. We use methods like blower door tests to pinpoint air leaks, and our Air Sealing Basement services are designed to tackle these common problem areas, ensuring your envelope is as tight as possible. This is vital, as 40% of the heating/cooling load in houses can be due to air infiltration.

Windows and Doors

These transparent and semi-transparent components are often the weakest links in a thermal envelope. Their thermal performance is measured by their U-factor (thermal transmittance), which indicates how readily heat flows through them. A lower U-factor means better insulating properties. The Solar Heat Gain Coefficient (SHGC) measures how much solar radiation passes through, impacting cooling loads. High-performance windows and doors, combined with proper weatherstripping and expert installation, are essential for a truly efficient envelope.

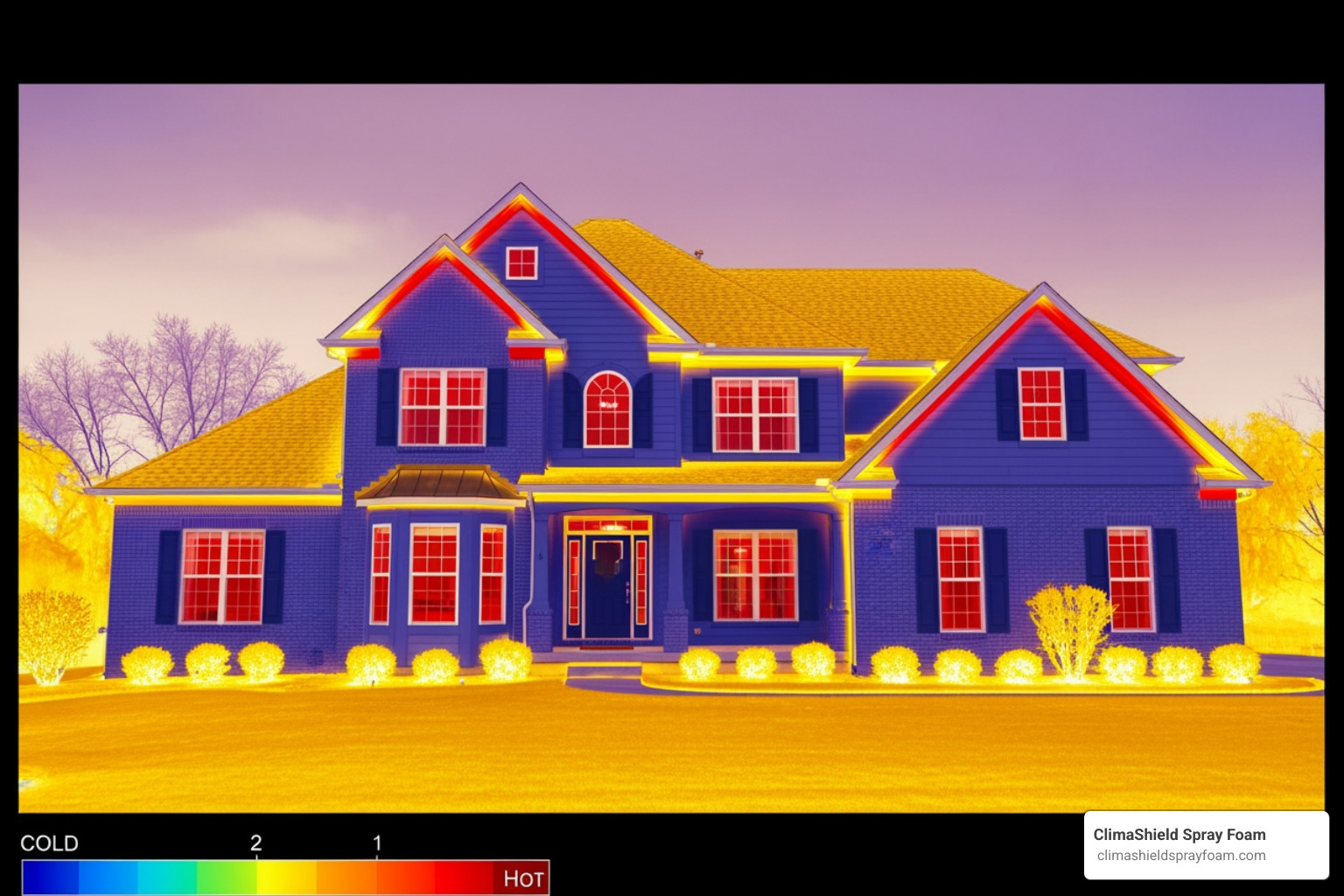

The Weak Link: Understanding Thermal Bridges

Even the best-insulated buildings can suffer from “heat bridges,” also known as thermal bridges, “cold bridges,” or “thermal bypasses.” These are areas where it’s easier for heat or cooling to move in or out of a building, essentially bypassing the insulation. Think of them as “gaps” in your building’s warm coat.

Common locations for thermal bridges include:

- Structural elements: Wood or metal studs in walls, concrete slabs extending beyond the insulated envelope.

- Junctions: Where walls meet roofs, floors, or foundations.

- Penetrations: Around windows, doors, pipes, or electrical outlets.

- Balcony connections: Where a concrete balcony extends from a conditioned space.

The impact of thermal bridges can be significant. They reduce the overall effectiveness of your insulation, leading to localized cold spots, increased energy loss, and a higher risk of condensation—which can cause mold and moisture damage. Preventing thermal bridges is essential for maintaining comfortable indoor conditions in low-energy buildings, as emphasized by Passive House principles. Achieving a truly thermal bridge-free design often requires individual planning methods custom to the specific construction and materials, ensuring continuous insulation and airtightness. This is where seamless insulation solutions like spray foam truly shine, wrapping around complex geometries to eliminate these weak links.

Measuring Performance: U-Factor, R-Value, and Airtightness

To truly understand and optimize a building thermal envelope, we rely on specific performance metrics:

- U-factor (Thermal Transmittance): This measures the rate of heat transfer through a given assembly (like a wall, window, or roof). A lower U-factor indicates better insulating properties and less heat loss or gain.

- R-value (Thermal Resistance): This measures an insulation material’s ability to resist heat flow. A higher R-value means better insulation. The U-factor and R-value are inversely related: U = 1/R.

- Thermal Transmittance Calculation: For a composite assembly like a wall or roof, the overall U-factor is calculated by taking the inverse of the total thermal resistance (R-value) of the assembly. This total resistance is the sum of the resistances of each individual layer, including the interior and exterior air films. The resistance of each material layer is determined by its thickness divided by its thermal conductivity. This calculation helps us understand the performance of multi-layered components.

- Airtightness Measurement: We assess airtightness using techniques like blower door testing. This involves depressurizing or pressurizing the building to measure the amount of air leakage, often expressed as Air Changes per Hour (ACH). A low ACH indicates a very tight, energy-efficient envelope.

These calculations and measurements allow us to precisely quantify performance, identify areas for improvement, and ensure that our insulation and air sealing solutions deliver maximum impact for your building.

Common Challenges and Advanced Solutions

Designing and improving building thermal envelopes comes with its share of challenges, especially when dealing with existing structures. However, advanced solutions are constantly evolving to overcome these problems.

A challenge in existing buildings is simply identifying where the problems lie. Leaks and inadequate insulation are often hidden behind finished surfaces, making them difficult to detect. Then there’s the cost-benefit analysis: how much should you invest in improvements, and what will the return be? Complex building geometries, common in older homes or unique architectural designs, can also make it difficult to ensure continuous insulation and airtight layers. Finally, managing moisture within the envelope while simultaneously achieving airtightness requires careful planning to prevent issues like condensation and mold, which is why balancing airtightness with adequate ventilation is key.

Improving the Building Thermal Envelope in Existing Structures

For existing buildings in Indiana, PA, and across Pennsylvania, improving the thermal envelope often begins with a thorough assessment. We use tools like energy audits, blower door tests, and infrared thermography to pinpoint exactly where heat is escaping and where air leaks are occurring. These diagnostic steps are crucial for developing a targeted and effective improvement plan.

Common improvements include:

- Adding insulation: Upgrading insulation in attics, walls, and basements.

- Air sealing: Sealing cracks and gaps around windows, doors, and utility penetrations.

- Window and door replacement: Upgrading to high-performance units.

We place particular emphasis on areas like attics and basements, which are often significant sources of energy loss. Our spray foam solutions are ideal for retrofits because they expand to fill irregular cavities, create an effective air barrier, and adhere to various surfaces, ensuring a continuous thermal and air control layer even in challenging existing constructions. This approach directly addresses the “tight” envelope goal, making a noticeable difference in comfort and energy bills.

Advanced Materials and Technologies

The field of building thermal envelopes is constantly innovating, with new materials and technologies pushing the boundaries of energy efficiency.

- Advanced Insulation: Spray foam insulation is a prime example. Its ability to create an airtight seal while providing excellent thermal resistance makes it a superior choice. As detailed in our Uses of Spray Foam guide, it’s durable, waterproof, and resists mold and pests, offering long-term performance.

- High-Performance Windows and Doors: Modern fenestration features multiple panes, inert gas fills, low-emissivity coatings, and thermally broken frames to drastically reduce heat transfer and solar gain. Paired with meticulous weatherstripping, these components minimize energy waste.

- Cool Roofs: Especially beneficial in warmer climates or during hot Pennsylvania summers, cool roofs use materials with high solar reflectance and thermal emittance to reflect sunlight and release absorbed heat. While specific regulations might vary by region, organizations like the Cool Roof Rating Council (CRRC) provide standards for these products. We can apply compatible coatings over spray foam roofing systems to achieve excellent cool roof performance.

- High-Performance Wall Systems: These often integrate continuous insulation layers, advanced air and vapor barriers, and thermally broken structural elements to achieve exceptional U-factors. Spray foam insulation can be a key component in these systems, delivering a monolithic, high-performance solution that significantly outperforms traditional batt insulation.

Frequently Asked Questions about the Building Thermal Envelope

How are thermal envelope performance standards regulated?

Thermal envelope performance standards are crucial for ensuring energy-efficient construction, and they are regulated through various codes and guidelines. In the United States, the International Energy Conservation Code (IECC) is widely adopted by states and municipalities, including throughout Pennsylvania. The IECC sets minimum requirements for insulation levels, window performance, and airtightness for both residential and commercial buildings.

Alongside the IECC, ASHRAE standards (from the American Society of Heating, Refrigerating and Air-Conditioning Engineers) also provide comprehensive guidelines for energy efficiency in buildings. These codes typically offer two paths to compliance:

- Prescriptive Path: This involves meeting specific R-value or U-factor requirements for each component of the envelope (e.g., walls must have R-15 insulation).

- Performance Path: This allows for more flexibility, where the overall energy performance of the building must meet a certain threshold, even if individual components don’t strictly adhere to prescriptive values. This path allows designers to optimize the entire system.

Mandatory requirements, such as continuous insulation in certain wall types or specific air barrier installation, are also common. For detailed guidance specific to our region, we often refer to resources like the IECC Compliance Guide for Homes in Pennsylvania and [[PDF] IECC Compliance Guide for Homes in Pennsylvania](https://efficientwindows.org/wp-content/uploads/codes2018/Pennsylvania2018.pdf).

What is the relationship between the thermal envelope and renewable energy?

The relationship between your building’s thermal envelope and renewable energy integration is fundamental, often summarized by the “fabric-first” approach. This philosophy dictates that you should first optimize the building itself—its “fabric,” or thermal envelope—to reduce energy demand as much as possible, before adding renewable energy generation systems like solar panels.

Think about it: if your building is leaky and poorly insulated, a significant portion of the renewable energy you generate will simply be wasted, escaping through an inefficient envelope. A tight, well-insulated thermal envelope drastically reduces your heating and cooling loads, meaning you need less energy to begin with. This makes renewable energy systems, such as solar photovoltaic (PV) arrays or high-efficiency heat pumps, far more effective and cost-efficient. By minimizing demand, a high-performance envelope enables smaller, more affordable renewable energy systems to meet a larger percentage—or even all—of your building’s energy needs, paving the way for truly Net Zero Energy buildings.

How do you fix a thermal bridge?

Addressing thermal bridges is crucial for optimizing your building thermal envelope. The approach depends on whether you’re working with new construction or an existing building.

In New Construction:

The best strategy is to prevent thermal bridges through careful design. This often involves:

- Continuous Exterior Insulation (CI): Applying a layer of insulation, such as rigid foam or continuous spray foam, on the exterior of the structural framing. This creates an uninterrupted thermal barrier, minimizing heat flow through studs or other structural elements.

- Thermal Breaks: Incorporating non-conductive materials (thermal breaks) in structural connections, like between a concrete balcony and the building’s floor slab, to interrupt the path of heat transfer.

- Thoughtful Framing: Designing wall assemblies to minimize the amount of framing material that penetrates the insulation layer.

Spray foam is particularly effective in new construction because it can be seamlessly applied to create both a continuous insulation layer and an air barrier, effectively wrapping the building in a high-performance “coat.”

In Existing Buildings:

Fixing thermal bridges in existing structures can be more challenging but is often achievable:

- Adding Insulation: Applying interior or exterior insulation over bridging elements. For example, insulating the interior side of an exterior wall with spray foam can cover the studs and create a more continuous layer.

- Insulated Sheathing: Installing insulated sheathing on the exterior of walls during a re-siding project can add a continuous layer of insulation.

- Sealing Penetrations: Carefully sealing around windows, doors, and utility penetrations with appropriate sealants and spray foam to close gaps that act as small thermal bridges.

The goal is always to create the most continuous thermal and air barrier possible, even if it means retrofitting existing components. Our team at ClimaShield specializes in identifying these weak points and implementing solutions, often leveraging the versatility and effectiveness of spray foam, to significantly improve your building’s thermal performance.

Conclusion: Sealing in Savings and Comfort

As we’ve explored, the building thermal envelope is far more than just the walls and roof; it’s the fundamental system that dictates your building’s energy consumption, occupant comfort, and long-term durability. A well-designed, “tight” envelope is like a perfectly custom, warm coat for your building, sealing in comfort and sealing out energy waste.

Embracing the “fabric-first” approach—prioritizing a high-performance thermal envelope—is the smartest investment you can make in any building, whether residential or commercial. It leads to substantial energy savings, reduces your carbon footprint, and creates healthier, more comfortable indoor environments.

For professional assessment and high-performance insulation solutions like spray foam, trust the experts at ClimaShield Spray Foam. We’re dedicated to helping homes and businesses in Indiana, PA, and across Pennsylvania achieve peak energy efficiency. Take the next step towards a more efficient building by exploring our Commercial Insulation services, and let us help you seal in savings and comfort for years to come.